Socket Pin Types & Relay Compatibility: OEM Solutions from China

Selecting the right socket pin for a relay seems simple—until you discover the variety of pin diameters, materials and brand‑specific pin arrangements. Engineers and buyers often struggle with mismatched socket pins that cause poor connections, overheating or early failure. This guide decodes common socket pin types and explains how pin size, plating and brand‑specific conventions affect relay socket compatibility. It also explores how cost‑effective OEM pins from China meet international standards and help you build reliable industrial control panels.

TL;DR

Understand pin types and sizes – Different relays use plug‑in pins, PCB pins or DIN‑rail terminals. Pin pitch (3.5 mm, 5 mm etc.) dictates whether a socket accepts certain relays. Selecting the wrong pin size leads to loose or damaged connections.

Consider materials and plating – Socket pin contacts are made from copper alloys such as brass, phosphor bronze or beryllium copper; they are usually tin‑, silver‑ or gold‑plated to enhance conductivity and prevent corrosion. Tin plating is cost‑effective and provides good solderability.

Check brand compatibility – Brands like Schneider, Siemens, IDEC, Finder and OMRON have specific pin arrangements and ratings. Choosing a compatible socket means matching pin pitch, coil voltage and contact configuration; look for UL94 V‑0 housings and certified products.

Verify electrical ratings – Pin current and voltage ratings depend on material and plating. High‑current applications may need silver‑plated contacts, while low‑signal circuits benefit from gold.

Leverage OEM sources – High‑quality socket pins from Chinese OEMs offer customisation, compliance with IEC/UL standards and cost advantages. Working with a reputable supplier ensures durability, testing and global shipping.

Socket Pin Types and Size Standards

Socket pins are the conductive terminals inside relay sockets that mate with the relay’s plug‑in pins or solder to a PCB. Choosing the correct pin type requires understanding pin pitch, diameter and mechanical form:

Plug‑in versus PCB pins – Plug‑in pins (sometimes called “socket terminals” or “relay plug pins”) protrude from the relay and insert into a socket. PCB pins are straight, short leads designed to be soldered onto a printed circuit board. The socket pins must match the style: a socket with long blade contacts may not hold a relay designed for solder tails.

Pin pitch and size – Manufacturers assign codes to indicate pin pitch. In Finder’s 40‑series, the second group of digits denotes pin pitch: 3 for 3.5 mm PCB mounting, 5 for 5 mm plug‑in or PCB mounting and 6 for 5 mm plug‑in mounting. A 5‑mm pitch socket accepts relays from Schneider or Siemens with similar spacing, while a 3.5‑mm pitch is typical for compact PCB relays. Always consult the relay datasheet for pin spacing to prevent misalignment.

Number of pins – Socket designs correspond to the number of relay poles and contacts. Single‑pole single‑throw (SPST) relays have fewer pins than double‑pole double‑throw (DPDT) relays. Terminal designations follow standards like EN 50005, where pins are numbered (e.g., 11‑12‑14 for common, normally closed and normally open). Matching these numbers ensures correct wiring.

Terminal form – Socket pins may be round or flat. Round pins typically insert into spring clips, while flat blade pins mate with fork terminals. Some sockets combine both (mixed‑pin) to allow flexible wiring.

The result of mismatching pin type or size is unreliable connection and potential arcing. For example, forcing a 5 mm relay into a 3.5 mm socket stretches the contacts and reduces spring force. Conversely, a socket pin that is too large can crack the relay’s case. Engineers should prepare a socket pin chart showing available diameters (2 mm, 3.1 mm, 4.8 mm etc.) and corresponding relays to simplify selection.

| Pin Pitch (mm) | Typical Diameter/Width | Compatible Brands / Series | Application Notes |

|---|---|---|---|

| 3.5 mm | ~2.0 mm round pins | Finder 40 series (3.5 mm PCB type) | Compact PCB-mount relays, space-saving designs |

| 5.0 mm | ~3.1 mm round/flat pins | Schneider RXM series, Siemens 3RH series, Finder 40/55 series (5 mm version) | Most common size, widely compatible with plug-in industrial relays |

| 6.3 mm | ~4.8 mm flat blade pins | Heavy-duty relays or contactor bases (e.g., some ABB / TE Connectivity models) | High-current applications, designed for spade/fork terminals with strong mechanical stability |

Key Takeaways

Pin pitch matters – Always match the relay’s pin spacing to the socket pitch (e.g., 3.5 mm vs. 5 mm).

Pin style must match – Choose plug‑in sockets for plug‑in relays and PCB sockets for soldered pins.

Use a pin chart – Document pin diameters, number of pins and series to avoid mismatched installations.

Internal link: Learn more about PCB‑level relay socket parameters on our product page.

Materials, Plating and Electrical Ratings

The performance and longevity of a socket pin depend largely on the metals used and the surface finish. Socket pins must conduct electricity, maintain spring tension and resist corrosion under repeated insertions. To achieve these goals manufacturers employ specific copper alloys and protective platings:

Copper‑based alloys – Common base materials include brass (copper‑zinc), phosphor bronze (copper‑tin‑phosphorus) and beryllium copper. Brass is cost‑effective and offers good conductivity but can lose spring tension at high temperatures; therefore it is often tin‑plated for durability. Phosphor bronze provides higher elasticity and wear resistance, maintaining contact force under repeated insertions. Beryllium copper combines excellent conductivity with superior spring strength, making it ideal for high‑vibration applications

Tin plating – Tin is an economical finish that offers good solderability, corrosion resistance and ductility. According to KC Jones Plating, tin plating “involves applying a thin layer of tin material onto a metal surface to provide protection and enhance electrical conductivity”. It protects against humidity and acids and has high lubricating properties—useful for plug contacts. Tin plating is available in bright (high gloss, excellent current‑carrying capability) and matte (superior solderability) finishes.

Silver and gold plating – For higher currents or critical circuits, contacts may be silver‑ or gold‑plated. The Tyco/TE definitions note that silver‑tin‑oxide (AgSnO₂) contacts have low welding tendency and high wear resistance, while gold plating provides the best corrosion resistance for low‑voltage applications. Gold is seldom used on power relays due to cost, but it ensures stable contact resistance in signal circuits.

Nickel underlays – Many tin or silver plated contacts have a nickel barrier layer to prevent copper diffusion. Nickel improves solderability and adds hardness.

For readers seeking more technical detail, consult the TE Connectivity definitions document and the KC Jones tin plating guide. The definitions document (an annex to IEC 61810‑1) lists common plating and contact materials for relays and explains their performance differences, while the KC Jones guide outlines why tin plating offers excellent electrical conductivity, corrosion resistance and cost efficiency. These external resources complement the overview in this section and are linked here for convenience: TE Connectivity definitions and KC Jones tin plating guide.

These material choices determine current rating and voltage rating. For instance, tin‑plated brass contacts are suitable for general‑purpose relays up to 10–15 A; silver‑plated beryllium copper contacts can handle 16–30 A. Always consult the datasheet for specific ratings. Also, ensure that the housing material meets UL94 V‑0 flammability standards; IDEC’s RJ relay sockets use flame‑retardant plastic (UL94 V‑0) and are UL/CSA/EN certified. This ensures the pin insulation won’t propagate fire in the event of overheating.

Key Takeaways

Choose the right alloy – Brass is economical but may relax at high temperatures; phosphor bronze and beryllium copper maintain spring force.

Select plating for the application – Tin plating is cost‑effective and good for solderability; silver is used for heavy loads; gold suits sensitive, low‑current circuits.

Check ratings and certifications – Pin materials and plating affect current/voltage ratings; choose UL94 V‑0 rated housings for fire safety.

Internal link: Explore our durable relay socket pins and plating options here.

Brand‑Specific Compatibility and Standards

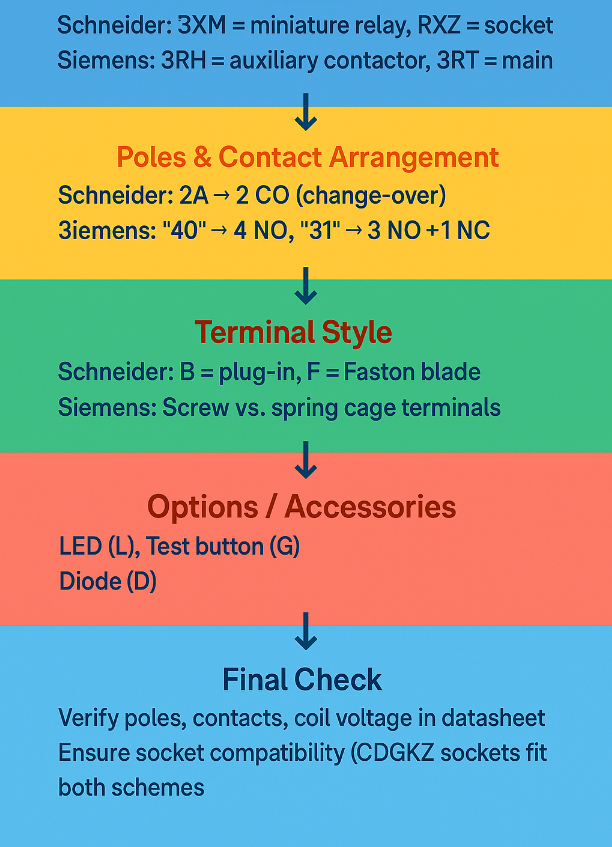

Major relay manufacturers adopt different pin arrangements, pin codes and standards, so cross‑brand compatibility requires careful matching. Here are key considerations when integrating socket pins with relays from Schneider, Siemens, IDEC, Finder and OMRON:

Pin arrangement and numbering – Schneider’s Harmony RXM relays use plug‑in pins with 5.0 mm pitch; Siemens’ SIRIUS 3RH/3RT series employ similar pitches but might have different terminal layouts. Pin numbers follow standards like EN 50005 (common = 11, normally closed = 12, normally open = 14), which ensures that coils and contacts are wired consistently across brands. Always compare the relay’s terminal diagram with the socket’s pin layout.

Coil voltage and contact form – Relay part numbers encode coil voltage and contact arrangement (e.g., 2CO, 3NO+1NC). The socket must accommodate the correct number of pins. For example, a double‑pole double‑throw (DPDT) relay has eight terminal pins; using a socket designed for a single‑pole relay would leave unused pins unconnected. Ensure the socket’s contacts match the relay’s rated voltage and current; some sockets include integrated coil suppression circuits or LED indicators.

Compliance and flame resistance – Many European and North American markets require sockets to meet IEC 61810‑1 and UL/CSA standards. IDEC’s RJ sockets highlight that their body material is UL94 V‑0 flame‑retardant and the products are UL, CSA and EN compliant. Using certified sockets reduces liability and ensures safe operation.

Cross‑reference tables – To simplify selection, create a cross‑reference chart of brand models versus compatible socket pins. For example, Finder’s 40.52 series (double‑pole, 5 mm plug‑in) uses a particular socket pin style; Schneider’s RXM2AB2P7 and Siemens’ 3RH2140‑1AP00 require similar pins. Listing these together helps procurement teams choose OEM replacements.

Remember that some brands use unique features (e.g., Siemens’ spring‑cage terminals or OMRON’s test button), so choose sockets that support these features. When in doubt, consult cross‑reference guides or contact your supplier for compatibility assistance.

Key Takeaways

Match the layout – Pin numbering and pitch differ by brand; cross‑check relay diagrams to ensure pin alignment.

Observe standards – Use sockets with UL/CSA/IEC certifications; flame‑retardant housings (UL94 V‑0) improve safety.

Use cross‑reference charts – Mapping relay model codes to compatible sockets prevents misapplication and streamlines sourcing.

Internal link: Consult our relay socket compatibility chart here.

OEM Sourcing, Durability and Installation

Sourcing socket pins from a trusted OEM in China offers substantial benefits when balanced with quality and compliance. Here’s why many industrial control manufacturers choose Chinese partners:

Cost‑effective manufacturing – China’s mature supply chain and economies of scale allow OEM suppliers to produce relay sockets and pin contacts at lower cost without compromising materials. Savings can be reinvested in better plating (e.g., thicker tin or silver) and rigorous quality control.

Customisation and flexibility – OEM manufacturers can adapt pin length, diameter, plating thickness and insulation colours to customer specifications. This is essential for designers seeking unique socket pin alternatives to big brands or for creating proprietary modules. Custom sockets can integrate additional features such as built‑in surge suppressors or indicator LEDs.

Compliance and testing – Reputable Chinese OEMs supply products that meet international standards (IEC 61810‑1, UL 508, RoHS). They perform socket pin durability tests (e.g., insertion/extraction cycles, vibration and corrosion testing) to ensure long service life. Using copper alloys and plating combinations recommended by industry experts—such as tin‑plated brass or silver‑plated beryllium copper—ensures that contacts maintain low resistance and spring force.

Comprehensive installation support – OEMs often provide socket pin installation guides with wiring diagrams, torque specifications for screw terminals and recommended stripping lengths. Proper installation is critical; over‑tightening screws can strip threads, while under‑tightening reduces clamping force. Follow the guide to ensure reliable socket pin terminal connections.

Global logistics and supply assurance – Many Chinese manufacturers maintain regional warehouses and logistic partners, ensuring timely delivery. Bulk orders reduce shipping cost per unit and provide a buffer against supply chain disruptions.

When selecting an OEM partner, examine their certifications, facility audits and customer references. High‑quality suppliers will be transparent about materials (brass, phosphor bronze, beryllium copper) and plating (tin, silver, gold) and will share test reports on current and voltage ratings. Building relationships with such suppliers ensures that your industrial control equipment uses robust and standards‑compliant socket pins that match or exceed the quality of big‑brand products.

Key Takeaways

Cost savings with quality – Chinese OEMs offer economical socket pins with high‑quality materials and plating.

Customisation and testing – OEM suppliers provide customised pin dimensions, plating options and durability tests to ensure reliability.

Installation guides matter – Follow manufacturer instructions for proper terminal torque and wire stripping to maintain strong connections.

Internal link: Get a quote for our cost‑effective relay socket pins here.

FAQ

Q1. What materials are used for relay socket pins?

Most relay socket pins are made from conductive copper alloys like brass, phosphor bronze or beryllium copper. Brass is economical but loses spring tension at high temperatures, so it is often tin‑plated. Phosphor bronze and beryllium copper retain spring force better and may be silver‑plated for higher current or gold‑plated for sensitive circuits.

Q2. Why is tin plating commonly used on socket pins?

Tin plating provides a protective layer that enhances electrical conductivity and solderability while preventing corrosion. KC Jones Plating notes that tin plating protects against humidity and acids and offers high lubricating properties. Bright tin is ideal for current‑carrying applications, while matte tin offers superior solderability.

Q3. How do I choose a socket pin that is compatible with my relay?

Check the relay’s datasheet for pin pitch (e.g., 3.5 mm or 5 mm), number of poles and contact arrangement. Ensure the socket’s pin pitch matches the relay’s plug pins and that the socket accommodates the required number of pins. Also, select sockets with UL/CSA/IEC certification and UL94 V‑0 rated housings to ensure safety.

Conclusion & Call to Action

Selecting the right socket pin is essential for reliable relay operation and long‑term safety. By understanding pin types, sizes and numbering standards, you can ensure proper relay socket compatibility. Choosing high‑quality materials and plating—such as tin‑plated brass for general use or silver‑plated beryllium copper for high‑current applications—improves conductivity, solderability and corrosion resistance. Certifications like UL/CSA/IEC and flame‑retardant housings ensure compliance with electrical safety standards.

As an OEM/ODM relay socket manufacturer in China, CDGKZ supplies cost‑effective, customizable socket pins and relay sockets that meet international standards. Our products use high‑grade brass, phosphor bronze and beryllium copper with tin or silver plating for optimal performance. We perform rigorous durability tests and provide installation guides, ensuring reliable connections in industrial control systems. Contact us today for samples, cross‑reference charts and competitive pricing. Let us help you build robust, compliant equipment with the right socket pins.