Selecting High-Quality Relay Socket Materials and Components

Introduction: Selecting the right relay socket materials is crucial for reliable, safe operation of electrical systems. Using low-grade sockets or the wrong materials can lead to overheated connectors, corrosion, or early failures – a serious pain point for engineers and buyers. In this guide, we explore high-quality relay socket materials for housings, contacts, and other components, and how proper material choices ensure durability and performance in demanding applications.

TL;DR Highlights:

– Robust Insulating Housings: High-quality relay socket housing materials are typically flame-retardant plastics (e.g. glass-filled nylon or PBT) or ceramics for extreme heat. These insulating materials resist heat and electrical tracking to keep connections safe.

– Durable Metal Contacts: Relay socket contact materials and terminals are made from conductive metal alloys (like brass, phosphor bronze, or beryllium copper) with corrosion-resistant platings (tin, silver, etc.). Quality metal parts ensure low resistance and long-term reliability.

– Heat & Corrosion Resistance: Using materials with high resistance to heat and corrosion prevents issues like socket melting or oxidized contacts. This relay socket resistance to heat and use of corrosion-resistant materials ensures the socket performs under harsh conditions without degradation.

– Selection Guidelines: When performing relay socket component selection, check that housing plastics are UL94-V0 rated and suitable for the operating temperature, and that contacts use appropriate metal alloys/plating for the electrical load and environment. High-quality materials and adherence to standards guarantee durability and performance.

Relay Socket Components and Why Materials Matter

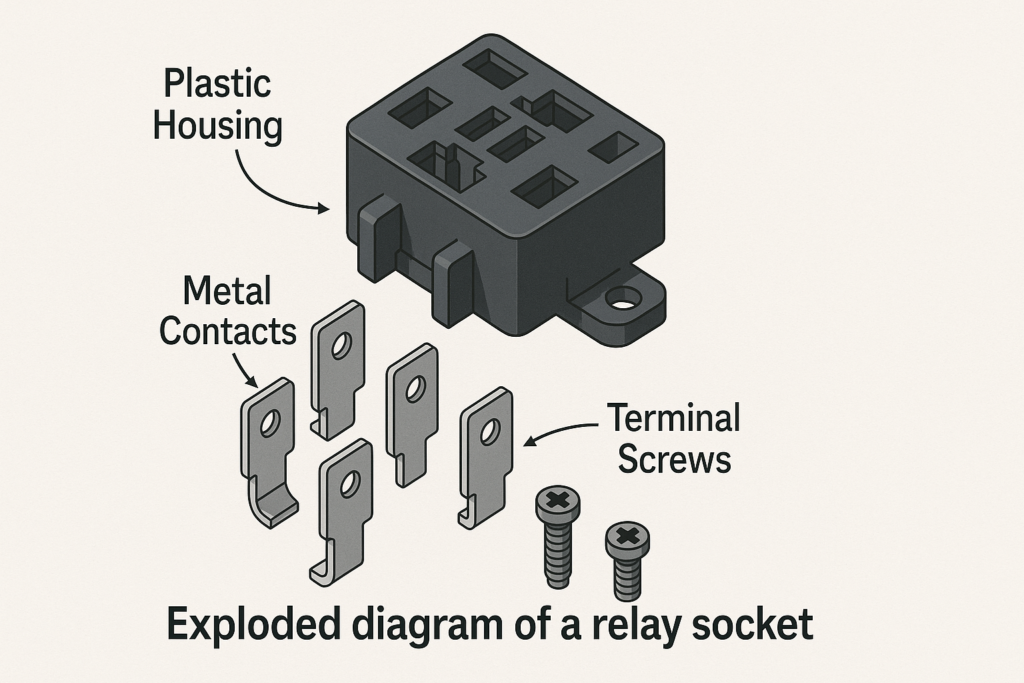

A relay socket typically consists of plastic insulating parts (the socket housing/base materials) and metal conductive parts (contacts and terminals). Each plays a distinct role and must meet specific requirements. The plastic components provide structural support and electrical insulation, while the metal components carry current. Both metal vs plastic components in a relay socket must work together reliably, so choosing suitable materials for each is critical.

Relay socket bases can be made from a variety of materials, including plastic, metal, and ceramic[1]. For example, a common 4PDT relay socket might use a nylon insulating body with spring brass contacts that are tin-plated for durability[2]. The material strength of the socket’s parts must withstand the mechanical stress of inserting/removing relays and any vibration in operation. If subpar materials are used – say, a low-quality plastic that softens with heat or brittle metal contacts – the socket can fail prematurely. Problems like loose connections, contact arcing, or melted housings often trace back to material quality issues.

High-quality relay sockets avoid these pitfalls by using purpose-chosen materials for each component. Insulating plastics have high dielectric strength and flame resistance, and relay socket metal parts are made of conductive alloys that maintain spring tension and resist corrosion. Understanding these components and their material requirements helps in selecting a reliable socket that will perform over time.

Key Takeaways:

– A relay socket is built from insulating plastic components (housing/base) and conductive metal components (contacts/terminals); each requires appropriate material properties for its function.

– Poor material choices (e.g. low-temp plastic or easily oxidizing metal) can lead to overheating, loose contacts, or electrical failure. Using high-quality relay socket materials prevents these common issues.

– Relay socket material strength and quality directly impact reliability – sturdy housings won’t crack or warp, and springy contacts won’t loosen, even under stress or repeated use.

Learn more about general-purpose relay specifications.

Relay Socket Housing, Base, and Insulating Materials

Relay socket housing materials must provide robust electrical insulation, structural support, and heat resistance. Most socket housings (including the base that mounts to a panel or PCB) are made from high-quality engineering plastics. Common insulating materials for relay sockets include thermoplastics like nylon (polyamide 6/6), polybutylene terephthalate (PBT polyester), or polycarbonate blends – all often enhanced with glass fiber for strength and higher temperature stability. Older or high-temperature designs may use thermoset phenolic resin (Bakelite) or even ceramic for exceptional heat resistance. The key is that the housing/base insulates the relay’s pins and maintains integrity under electrical and thermal stress.

High-quality plastics used in relay sockets are flame-retardant (typically rated UL 94 V-0 for self-extinguishing behavior[3]). For instance, many sockets use a rugged, glass-filled nylon that can operate from about -40 °C to 85 °C without deforming[4]. Such materials resist ignition and will self-extinguish within 10 seconds (V-0 rating) if ignited[5], a crucial safety feature. The housing must also handle the heat generated by the relay coil or contacts. Standard relay sockets are usually rated for operating temperatures up to around 70–85 °C[6]. Where higher ambient or coil temperatures are expected (e.g. near engines or high-current devices), manufacturers may opt for ceramic housings. Relay socket base materials like alumina ceramic can withstand very high heat (100 °C+); for example, an automotive ceramic relay socket is designed to handle up to 105 °C without failure[7]. Ceramic is inherently nonflammable and an excellent insulator, though it is more brittle and expensive than plastic.

Another consideration is environmental factors. Quality housing plastics have high Comparative Tracking Index (CTI) to resist electrical tracking in humid or dirty conditions, and low water absorption to maintain insulation. They also need adequate mechanical toughness. A socket’s plastic components should not crack under screw tightening or when snapping onto DIN rails. Using glass-reinforced polymers or high-performance resins ensures the socket base remains dimensionally stable at temperature and over time. In summary, relay socket plastic components are specially selected to be insulating, flame-resistant, and strong. Choosing the appropriate housing material (or ceramic, for extreme cases) is the foundation for a reliable relay socket.

Key Takeaways:

– Insulating Housing: Relay socket housings/bases are made of high-grade insulators (nylon, PBT, etc.) that resist heat and flame. Look for UL94 V-0 flame ratings on housing materials to ensure safety[3].

– Temperature Tolerance: Quality housing materials maintain rigidity and insulation up to the socket’s rated temperature (often ~85 °C for plastics). Ceramics are used for extreme heat resistance, tolerating 100 °C+ without melting[7].

– Structural Strength: Filled or engineered plastics provide mechanical strength. They resist cracking or warping under stress and environmental exposure, which is vital for socket longevity and environmental resistance (humidity, vibration, etc.).

Learn more about PCB socket parameters.

Relay Socket Contact and Terminal Materials (Metal Parts)

The relay socket contact materials and terminal hardware are the metal components responsible for electrical connection. These conductive materials must offer excellent electrical conductivity, mechanical spring properties, and corrosion resistance. Typically, contacts and terminals in relay sockets are made from copper-based metal alloys chosen for their balance of conductivity and strength:

- Brass (Copper-Zinc Alloy): A common, cost-effective choice for socket terminals. Brass has good conductivity and is easy to machine or stamp. However, it can lose spring tension at high temperatures. Thus, brass contacts are usually plated (e.g. tin-plated brass) to prevent tarnish and improve durability[2].

- Phosphor Bronze (Copper-Tin-Phosphorus Alloy): Often used for spring contacts, phosphor bronze offers higher elasticity and wear resistance than brass, albeit with slightly lower conductivity. It maintains contact force better under repeated insertions and elevated temps.

- Beryllium Copper (BeCu): A premium copper alloy used in high-quality sockets. BeCu combines good conductivity with exceptional spring strength. It’s considered an ideal spring contact material due to its high mechanical strength and favorable elastic modulus[8]. Beryllium copper contacts can handle many mating cycles without losing shape, making them suitable for critical or high-vibration applications.

To enhance performance, the metal contacts are almost always plated or surface-treated. Relay socket metal parts are exposed to air and electrical arcing, so plating prevents corrosion and lowers contact resistance. Common plating choices include:

- Tin Plating: Economical and provides good solderability and corrosion resistance. Most general-purpose relay sockets have tin-plated brass or bronze contacts for reliable performance.

- Silver Plating: Silver has the highest electrical conductivity of any metal. Heavy-duty or power relay sockets often use silver-plated contacts (over copper alloy) to handle higher currents with minimal voltage drop. Silver is also corrosion-resistant, though it can tarnish (form sulfide) over time. Still, under pressure of a socket contact, tarnish is usually not problematic for conductivity. For example, some industrial relay sockets use silver-plated beryllium copper contacts for optimal conductivity and longevity[9].

- Gold Plating: Gold is used in specialized applications, especially low-current or signal relays, because it never corrodes or oxidizes. It ensures extremely stable contact resistance over time. However, gold is costly. In practice, gold plating is less common on power relay sockets, but may appear on sockets for sensitive electronics. Both gold and silver are highly conductive and corrosion-resistant; however, silver can tarnish and gold is more expensive[10]. The choice depends on the use-case requirements.

Terminals where wiring connects (like screw clamps or PCB pins) are similarly made of brass or bronze and plated. Screws or clips might be steel or brass with nickel plating for strength. All metal interface points should be corrosion-resistant materials to ensure longevity. For instance, tin-plated copper alloy leads and terminals will resist oxidization in normal environments[11]. In aggressive environments (high humidity, salt air, etc.), using gold or a protective conformal coating might be advisable to maintain contact performance.

Notably, while polymers can be made slightly conductive (with carbon fill, etc.), relay socket conductive plastics are not used for primary contacts due to their much lower conductivity and mechanical robustness compared to metals. Metal alloys remain the standard for relay socket contacts because they can carry high currents, maintain spring tension, and withstand wear. The goal in material selection for contacts/terminals is to ensure low electrical resistance, firm contact pressure, and stability over thousands of cycles. High-quality sockets achieve this by using proven copper alloys and protective platings. As a result, the socket’s metal components reliably transmit power from the relay to the circuit without overheating or excessive voltage drop over the socket’s life.

Key Takeaways:

– Copper Alloys for Contacts: Relay socket contacts and terminals are typically made of copper alloys (brass, phosphor bronze, beryllium copper) chosen for conductivity and springiness. Premium metal alloys like beryllium copper provide superior spring retention[8] for long-term reliability.

– Plating for Performance: Contacts are plated (tin for general use, silver for high current, or gold for precision) to prevent oxidation and lower resistance. For example, silver-plated contacts offer very low contact resistance and handle heavy loads without corroding[9]. Plating selection affects relay socket contact performance and longevity.

– Corrosion Resistance: All metal parts should be corrosion-protected. Relay socket terminal materials with tin or noble metal plating won’t rust or tarnish easily, ensuring stable connections. High-quality sockets use corrosion-resistant materials so that electrical contacts remain clean and conductive over years of service.

Learn more about connector contact materials and plating.

Heat, Corrosion, and Durability Considerations

Even the best materials must withstand real-world operating conditions. Key performance considerations for relay socket materials include heat tolerance, resistance to corrosion, and overall durability. Using high-quality relay socket materials directly contributes to each of these factors:

- Heat Resistance: Relays can run warm due to coil power dissipation or carry high currents that heat up contacts. Socket materials must have sufficient relay socket resistance to heat to avoid deforming or degrading. Insulating plastics in the housing are often rated for continuous use up to 80–105 °C as discussed (and short-term soldering temps if PCB-mounted). If a plastic with too low a heat rating is used, the socket could soften or melt, especially near power contacts – a safety hazard. Metals too must handle heat: spring contacts should resist annealing (losing spring tension) at elevated temperatures. High-temp alloys like beryllium copper and the use of ceramics for insulation help sockets thrive in hot environments. For example, a ceramic relay socket can handle engine-bay temperatures (105 °C+) without issue[7]. Always check the socket’s operating temperature range against your application’s worst-case temperature to ensure a match.

- Flammability & Safety: Related to heat resistance is flammability. In the event of extreme overheating or an external fire, the socket’s materials should not fuel a fire. That’s why using UL94 V-0 rated plastics is a de facto requirement – a V-0 plastic self-extinguishes flames within 10 seconds and won’t drip flaming particles[5]. High-quality sockets will explicitly list compliance with safety standards (UL, IEC) for flammability. This is crucial in industrial or building electrical installations to meet code requirements.

- Corrosion and Oxidation: Over time, metal contacts can corrode from exposure to oxygen, moisture, or pollutants, leading to increased electrical resistance or intermittent connections. Relay socket corrosion-resistant materials prevent this. As noted, tin-plating or noble metal plating on contacts forms a protective barrier against oxidation. Additionally, using alloys that form stable oxides (e.g. copper alloys) rather than iron-based metals prevents rust. If a socket will be in a harsh environment (outdoors, coastal, or industrial atmosphere), corrosion resistance is a top priority – for instance, gold or heavy tin plating, and even stainless-steel hardware for screws/clips. On the insulating side, plastics should resist UV light and not absorb too much moisture (which could lead to electrical leakage paths). Quality fiberglass-reinforced thermoplastics and thermosets have good weathering properties, and ceramics are impervious to rust or rot altogether. A practical example: an automotive high-quality relay socket uses tin-coated copper leads specifically to withstand humid, salty conditions without corroding[11].

- Durability and Mechanical Strength: Relay socket durability materials are those that maintain their properties over many years and cycles. This includes mechanical durability – the socket should survive numerous relay insertions/removals and any vibration or shock. Materials like beryllium copper provide contacts that won’t crack or deform even after thousands of mating cycles, preserving contact force. Plastics with fiber reinforcement or tough polyamides ensure the housing doesn’t chip or break if the relay is knocked or during maintenance. Good material choices also prevent material creep (deformation under long-term load), so terminals and screws stay tight. Environmental durability is another aspect: exposure to temperature cycles, chemicals, or sunlight should not rapidly degrade the materials. For example, PBT polyester is often used because it has excellent dimensional stability and chemical resistance (it’s commonly used in automotive connectors for this reason). Ultimately, durable materials translate to a longer service life for the socket – meaning fewer replacements and more reliable system performance.

- Metal vs Plastic Component Synergy: It’s worth noting that relay socket metal vs plastic components must be selected in harmony. The insulating housing should firmly support the metal contacts in position, and the contacts’ material should be compatible with the housing’s assembly process (e.g. insert molding, soldering heat). A strong housing material can be undermined if the contact metal is too weak (leading to loose pins), and vice versa. High-quality sockets are engineered so that both the plastic and metal materials complement each other – the result is a socket that retains tight electrical connections and structural integrity throughout its life.

By considering these factors – thermal rating, flame class, corrosion protection, and mechanical robustness – engineers can evaluate whether a relay socket’s materials are up to the task. Reputable manufacturers will provide data on operating temperature range, certifications (like UL 508 or IEC compliance), and material details. In summary, the performance and longevity of a relay socket are largely determined by the materials chosen for its construction. Opting for a socket made with durable, heat-resistant, and corrosion-proof materials ensures high reliability, even in harsh environments.

Key Takeaways:

– Heat & Flame Tolerance: Choose sockets with materials rated for your operating temperature (and safety margins). High-temperature plastics or ceramics prevent heat-related failures, and UL94 V-0 flame-retardant housings enhance safety[3][5].

– Corrosion Resistance: High-quality sockets use plated contacts and corrosion-resistant metals, so connections stay clean over time. In harsh environments (humidity, salt, etc.), prioritize sockets with protective coatings (e.g. tin, silver, gold) and robust materials to avoid oxidation[11].

– Rugged Durability: Relay socket material strength underpins long-term durability. Tough housings and springy contacts made from premium materials will withstand mechanical stress (vibration, insertion cycles) and environmental aging, ensuring the socket’s performance remains stable for years.

Learn more about connector reliability in harsh environments.

Relay Socket Component Selection Guidelines

Selecting the right relay socket for your application means evaluating its components’ materials and ensuring they meet your requirements. Below are some guidelines for effective relay socket component selection:

- Housing/Insulator Material: Identify what material the socket housing is made of and its ratings. Relay socket housing materials should be flame-retardant (look for UL94 V-0 spec) and rated for a higher temperature than your maximum operating environment. For general purposes, a glass-filled nylon or PBT housing is usually sufficient (commonly rated around 85 °C). If the socket will be exposed to very high heat (e.g. near engines, or carrying high currents continuously), consider a socket with a ceramic or high-temperature thermoset base. Also ensure the housing can physically fit your mounting method (PCB socket vs panel mount) and that it’s robust (no flimsy thin plastic that could crack).

- Contact and Terminal Material: Check the metals used for the socket’s contacts or terminals. Relay socket contact materials are often listed in datasheets (e.g. “contacts: brass, tin-plated” or “phosphor bronze contacts with silver plating”). Make sure the metal alloy and plating are suitable for the electrical load. Brass or phosphor bronze with tin plating is fine for low-to-moderate currents and general environments. For higher currents or more demanding conditions, you might choose sockets with silver-plated contacts or even beryllium copper contacts for superior spring performance. The plating is important for contact performance – tin is good for most cases, but in corrosive or very low current situations, silver or gold plating might be preferable. Also consider terminal style: if it’s a screw terminal socket, are the screws steel or brass and are they plated to prevent rust? Quality sockets will advertise corrosion-resistant terminal hardware.

- Electrical Ratings & Standards: Ensure the socket’s material choices align with necessary electrical ratings. This includes the current and voltage rating of the socket (which are influenced by contact material and design) and any applicable standards. For instance, if you are designing industrial equipment, look for sockets that are UL Recognized or CE marked – this often implies they used appropriate materials (flame-retardant plastics, etc.) to meet standards like UL 508. A socket that meets environmental resistance tests or standards (for temperature, flammability, vibration) will have documentation. Don’t hesitate to request a spec sheet to review the materials and ratings.

- Application Environment: Consider the environment in which the relay socket will operate and choose materials accordingly. In a dry, controlled environment (like inside a consumer device), standard materials will usually suffice. But in harsh environments – say an outdoor control box, a factory floor, or automotive under-hood – you need materials with extra durability. Corrosion-resistant materials (platings, stainless steel hardware), UV-stable and moisture-resistant plastics, and secure mounting features (maybe sockets with clips to hold relays against vibration) become important. For example, if the application is outdoors, a polyamide housing with UV stabilization or a silicone seal might be needed to prevent degradation. If the application involves frequent mating cycles, prioritize sockets with high spring-force contacts (phosphor bronze or BeCu) to maintain a good connection. Essentially, match the socket’s material capabilities to the demands of the environment to ensure longevity.

By following these guidelines, you can perform an informed relay socket component selection that emphasizes material quality. Always opt for sockets from reputable manufacturers who clearly state their housing plastic type and flammability rating, contact alloy and plating, and electrical ratings. High-quality components might cost a bit more upfront, but they pay off by preventing downtime and failures. In sum, choose relay socket durability materials and designs that meet or exceed the needs of your project to guarantee safe and reliable performance.

Key Takeaways:

– Match Materials to Needs: Select relay sockets with housing and contact materials suited to your application’s electrical and environmental requirements. For high-heat or harsh conditions, this may mean ceramic or specially rated plastics and premium contact platings (e.g. silver).

– Verify Ratings: Always check the socket’s specs for flame class (UL94 V-0 is ideal), temperature range, current capacity, and any compliance certifications. These specifications reflect the quality of materials used and ensure the socket can handle the job safely.

– Prioritize Quality: In relay socket component selection, prioritize build quality and material integrity over minimal cost. A high-quality socket with strong, heat-resistant insulation and reliable metal contacts will provide durable service and maintain contact performance far better than a cheaply made alternative.

Learn more about our range of high-quality relay sockets and components.

FAQ

Q1: What materials are used in relay socket housings and bases?

A1: Most relay socket housings (and bases) are made from thermoplastic insulating materials that are flame-retardant and heat-resistant. Common choices include Nylon (PA6/6) and PBT polyester, often reinforced with fiberglass for strength. These plastics are rated UL94 V-0 to self-extinguish flames for safety. In high-temperature applications, ceramic materials (like alumina) may be used for the socket base, since ceramics can withstand very extreme heat without melting. Older or specialized sockets might use phenolic resin (a hard thermoset plastic) for its excellent electrical insulation and heat resistance. In summary, the housing is usually a high-quality, insulating plastic (or ceramic for extreme conditions) designed to support the relay and insulate live contacts.

Q2: What metal parts are in a relay socket, and what are they made of?

A2: The metal parts of a relay socket are the contacts and terminals – essentially any component that conducts electricity or interfaces with the relay pins and wiring. These parts are typically made of copper-based alloys for good conductivity. Brass and phosphor bronze are very common contact materials; they provide a balance of electrical conductance and springiness. High-end or heavy-duty relay sockets might use beryllium copper contacts, which offer superior spring tension and can handle more insertion cycles. The metal contacts are usually plated with another metal: tin plating is widely used to prevent corrosion and aid solderability, while silver plating is found in sockets meant for higher currents (silver has exceptional conductivity and resists oxidation, though it can tarnish slightly). In some cases (especially for sensitive or low-current circuits), contacts might even be gold plated to completely prevent corrosion. Additionally, if the socket has screw terminals for wire connections, those screws are often steel or brass with nickel or tin plating for strength and corrosion resistance. All these metal parts – contacts, terminals, screws – are chosen and treated to ensure a reliable electrical connection that won’t degrade with time or environmental exposure.

Q3: How do I choose a high-quality relay socket for my application?

A3: To choose a high-quality relay socket, pay close attention to the materials and ratings of each component, as well as the demands of your application. Here’s a step-by-step approach: First, look at the socket’s housing material – make sure it’s a robust, flame-retardant plastic (like UL94 V-0 rated nylon or PBT). This ensures the socket can handle heat and won’t pose a fire risk. If your application involves high temperatures (for example, under a car’s hood or near high-current devices), consider sockets with high-temperature plastic or even ceramic housings. Second, examine the contact and terminal materials. High-quality sockets will specify using copper alloy contacts (brass, phosphor bronze, or beryllium copper) with a protective plating. Match this to your needs: for general use, tin-plated contacts are usually fine; for harsher conditions or higher currents, silver-plated (or even gold-plated) contacts might be worth it for extra reliability. Make sure the socket’s current and voltage ratings meet or exceed what your relay and circuit require – these ratings often reflect the quality of the contact materials and design. Third, consider the environmental factors: if the socket will face moisture, vibration, or corrosive elements, opt for designs advertised as heavy-duty or automotive-grade. Features like sealed housings, stainless hardware, or higher IP ratings can be important. Essentially, you want materials that are heat-resistant, corrosion-resistant, and durable in the long term. Lastly, buy from reputable manufacturers who adhere to standards (such as UL or IEC). They are more likely to use high-quality relay socket materials and have done rigorous testing. Reading datasheets or product specs can provide insight – look for mention of material types and compliance standards. By verifying these details, you can confidently select a relay socket that will be safe, reliable, and long-lasting in your specific application.

Conclusion: The reliability of any relay-based system often comes down to the quality of the relay socket materials and components. By investing in sockets with high-grade insulating housings and robust, well-plated metal contacts, you ensure safe, low-resistance connections that stand the test of time. In short, choosing the right materials means your relays will perform optimally with fewer failures.

Ready to enhance your designs with dependable relay sockets? We offer a full range of relay sockets built with high-quality plastic housings and premium metal contacts for maximum durability. Contact our team today for expert guidance or to request a quote on the ideal relay socket solution for your needs. We’re here to help you select the best components to keep your projects running flawlessly.