Relay Socket Not Powering Load? Troubleshooting Common Relay Issues

Introduction: When an industrial relay socket not powering a load brings your equipment to a halt, it can be frustrating and costly. Maintenance engineers and panel technicians often encounter relays that won’t energize their coils, intermittent relay switching that causes unpredictable machine behavior, or contacts that stick closed and refuse to release. Overheated sockets, false triggering from electrical noise, and other relay malfunctions can lead to downtime and safety risks. This guide addresses these pain points by examining why relays fail – from a relay coil not energizing to contact welding – and how to fix these issues quickly in the field.

TL;DR – Quick Tips:

Check Coil Power: Always verify the relay coil is receiving the correct voltage. A relay that won’t energize often has no control voltage or the wrong coil rating.

Inspect Wiring & Socket: Loose, reversed, or corroded wiring in the relay socket can prevent power from reaching the load. Tighten terminals and confirm connections match the wiring diagram.

Watch for Inrush & Overload: High inrush currents (e.g. motor start surges) can weld contacts or overheat sockets Use relays rated for the surge or add protection to prevent contact sticking.

Eliminate Chatter & Noise: Relay chatter (rapid on/off clicking) is usually caused by unstable coil voltage or electrical interference. Ensure a stable power supply and add snubbers or flyback diodes to filter noise.

Prevent False Triggers: Shield control wiring and use proper grounding. Electromagnetic interference (EMI) or induced voltages in long runs can spur false triggering of relays Filtering and shielding can help stop unintended relay activation.

Relay Not Energizing the Coil (No Output to Load)

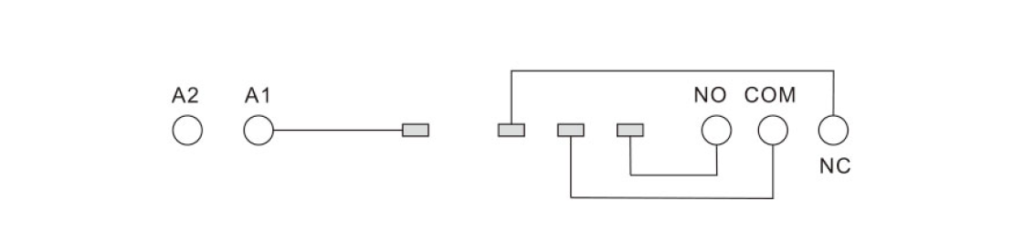

One of the most common faults is when a relay fails to energize at all – no clicking sound, no indicator light, and the connected load remains off. In this scenario, the coil is not being powered. Causes for a relay coil not energizing include the obvious (no control voltage applied due to an open circuit or blown fuse) and the subtle (wrong coil rated voltage, or wiring mistakes) Double-check that the correct control voltage reaches the coil terminals. For example, if a 24 V DC coil relay is placed in a 120 V AC circuit, it will never energize (coil voltage mismatch symptoms could also include coil overheating if overvoltage is applied). Likewise, ensure the coil terminals are wired properly according to the socket’s diagram – a socket wiring reversed or miswired pins will prevent the coil from energizing.

Another possibility is a damaged or open coil. Over time or due to surges, a relay coil can burn out (go open-circuit) and thus not draw any currentia.omron.com. If you suspect this, measure the coil’s resistance with a multimeter (with power off); an infinite or very high resistance indicates a failed coil that needs replacing. Some relay sockets have an LED indicator that lights when the coil is powered – if this LED indicator not lighting on the socket while it should, it’s a strong clue the coil isn’t receiving power or is open. Also consider mechanical issues: is the relay fully seated in its socket? An improperly seated relay or bent pin can break the circuit to the coil.

If the coil is energizing (you hear a click or see the LED on) but the load still isn’t powered, then the problem lies on the contact side. Possible causes are dirty or oxidized contacts, a wiring error on the output terminals, or even a contact sticking in the open position. Verify the load is connected to the correct contact terminals (common and NO/NC as required). It’s surprisingly easy to wire to the wrong socket terminals such that the load never gets power. Also inspect the contacts for corrosion or pitting – relay base corrosion issues or burnt contacts can prevent electrical continuity. In field troubleshooting, a quick way to diagnose a non-operational relay is to swap it with a known-good relay; if the new relay works, the original was likely bad (coil or contacts). If neither works, the issue is external (wiring or load problem).

Key Takeaways:

A relay coil that doesn’t energize often points to no or incorrect voltage at the coil – check supply, coil rating, and fuses.

Ensure the relay and socket are wired correctly. Loose or reversed coil wiring, or an incorrectly seated relay, can prevent coil activation.

If the coil energizes but no load power, inspect the contact wiring and condition. Burnt or corroded contacts or socket terminals may need cleaning or replacement.

Intermittent Switching, Chatter & False Triggering

Relays that switch intermittently or chatter rapidly can be both puzzling and damaging. Relay chatter is the rapid on-off cycling (audible clicking) of the contacts, often due to an unstable coil supply. If the coil’s voltage dips below its minimum holding value even briefly, the relay may drop out and re-energize repeatedly. Common causes include a weak power supply, voltage drop in long wires, or a driver circuit that isn’t supplying enough current. For instance, a large motor or solenoid on the same circuit might pull the voltage down when starting, causing the relay to momentarily release (voltage drop causing contact chattering has been observed when heavy loads start). The remedy is to ensure the coil has a stable, sufficient voltage at all times – use a regulated supply or separate the relay coil circuit from noise-heavy loads. If the relay has a DC coil, add a sufficient capacitor or noise filtering for the relay coil supply to smooth out dips (and always use a flyback diode across a DC coil to absorb the inductive kick when it de-energizes).

Another culprit is electromagnetic interference (EMI) or induced voltages on the control line. Long cable runs near motors or VFDs can pick up transients that falsely trigger the relay. In some cases, an unused input wire can act like an antenna and introduce spurious pulses. As an example, if you see an indicator LED flash or a relay trigger when a nearby machine turns on, suspect EMI. According to industry experts, EMI can induce noise pulses that the control system interprets as commands, leading to false triggers and unintended relay operation. To combat this, use shielded, twisted-pair wires for control signals and ground the shields properly. Keep control wiring separate from power cables to reduce coupling. You can also install snubber networks or MOVs on coils and contacts – not only do these protect against voltage spikes, they also absorb some high-frequency noise. For programmable controllers, adding a small RC filter or debouncing logic on the input that drives the relay can filter out microsecond noise spikes.

Mechanical vibration is another cause of intermittent relay operation. In high-vibration environments (e.g. on a machine or vehicle), the relay’s internal mechanism can literally be shaken, causing contacts to momentarily open. Standard plug-in relays might fail under vibration, especially if mounted vertically or if they have no retention clip. The quick fix is to secure the relay and socket firmly (use a mounting clip or DIN rail lock). For chronic vibration issues, consider “vibration-proof” relays with reinforced springs, or even solid-state relays (which have no moving parts to bounce).

Finally, relay not latching when energized can be related to the above issues. If a relay should stay activated but drops out too soon, ensure the coil voltage isn’t sagging or being cut off prematurely (for example, due to a control logic error or a protection circuit leaking current awayia.omron.com). Some relays are latching types (they stay in the last state without coil power); if one “not latching” is actually a latching relay failing to hold state, the issue could be mechanical or an internal magnet problem – replacement is usually the solution in that case.

Key Takeaways:

Chattering relays usually indicate unstable coil voltage or supply issues. Maintain proper voltage and use capacitors or a separate supply to avoid voltage dips.

False triggering can occur due to EMI or induced voltages. Shield and separate control wiring, and add snubbers or filters to block noise spike

In high vibration conditions, use vibration-resistant relays or solid-state relays. Securely mount relay sockets to prevent mechanical shock from causing contact bounce.

Overheating, Sticking Contacts, and Socket Failures

Electrical relays dealing with power loads can run into issues on the output side – namely overheated parts or contacts that stick closed. If you notice a relay socket overheating, discoloration, or a burning smell, address it immediately. Relay socket overheating reasons typically boil down to excessive current or poor connections. An over-current condition (drawing more amps than the relay or socket is rated for) will generate heat at the contacts and terminals. For example, forcing a 5 A-rated relay to control a 10 A load will cause it to run hot and likely fail. Always verify the steady-state current and also the inrush current of the load – many loads (motors, compressors, incandescent lamps, etc.) draw a high inrush current on startup, often 5-10 times their running current. Welding of contacts due to such excessive surge current is often the result, as TE Connectivity notes, and relays for high-inrush applications need to be oversized or specially designed. In practical terms, this means if you have a motor with 50 A startup surges, don’t use a relay rated exactly 50 A; use one rated significantly higher or a purpose-built high inrush relay. You can also add inrush current limiters or soft-start circuits to reduce the surge seen by the relay.

Even within rated limits, a loose or corroded connection at the socket can generate concentrated heating. A terminal screw that isn’t tight or a blade connector with oxidation creates resistance, which under load causes power dissipation (I²R losses). Over time this can char the socket plastic or wiring insulation. Imperfect contact with the socket pins is specifically noted as a heat source in relay failures. The fix is straightforward: tighten all screw terminals to the specified torque and ensure connectors are clean. If a socket shows signs of heat damage, replace it – continued use can lead to intermittent contact or fire hazard.

Contact sticking (welding) is a failure mode where the relay’s contact points fuse together, usually in the closed position. The next time the coil de-energizes, the circuit remains stuck on. High inrush or fault currents are a primary cause as mentioned. For example, switching a lamp load near the AC voltage peak can create a large arc and melt the contacts together. Once a relay’s contacts weld, the relay must be replaced; no amount of tapping will reliably fix it. To troubleshoot contact sticking, look for symptoms like the load staying on even when the relay coil is off, or measure continuity across the NO contacts with the coil removed – a welded relay will show continuity when it should be open. Preventative measures include using contact protection (RC snubbers, varistors) across inductive loads to absorb the energy that causes arcs, and selecting relays with contact materials and ratings suited for your load type. If a particular relay repeatedly fails with welded contacts, consider uprating to a heavier-duty unit or using two relays in parallel to share the load (rarely used, but sometimes done for high-power DC switching), or move to a contactor/solid-state relay designed for the stress.

Environmental factors can also degrade contacts and sockets. Corrosion on contacts or terminals (from moisture or corrosive gases) leads to increased resistance and heating, and can prevent a relay from conducting even when closed. In humid or chemical environments, use relays with sealed contacts or gold-plated contact surfaces for low currents. Regularly inspect the relay base and clean any rust or oxidation on terminals – ensure power is off and use appropriate electrical contact cleaner. If the socket terminals are heavily corroded or burned, it’s best to replace the socket entirely to restore reliability.

Surges and spikes (for instance, a lightning surge or switching surge on the line) can also damage the relay or socket insulation. Coil suppression devices (RC snubbers or MOVs) and surge protectors on supply lines help surge damage prevention for sockets and the overall circuit. These devices absorb transient voltage spikes that could otherwise arc across contacts or break down insulation in the relay coil.

Key Takeaways:

Do not exceed contact ratings. Over-current or high inrush conditions will overheat and can weld relay contacts. Choose relays with appropriate ratings and consider inrush limiters for large loads.

Ensure all connections are tight and free of corrosion. A loose terminal or oxidized socket pin creates resistance that causes heating and potential failure.

Use protective snubbers or surge suppressors on inductive loads. They reduce arcing and prevent contact welding and surge damage, extending the life of both relay and socket.

Maintenance, Test Buttons & Advanced Diagnostics

Even with proper component selection and installation, relays require maintenance and periodic testing – especially in critical applications. Many industrial relay sockets feature a manual test button or lever. This allows technicians to activate the relay by hand (to test circuit function) or lock the relay in a given state. If this test button is left in the wrong position or becomes faulty (stuck), it can cause the relay to misbehave. For example, a latched test button might keep the relay contacts closed (or open) regardless of coil commands. Troubleshooting a faulty test button involves first removing power for safety, then manually checking if the button is jammed or locked. Most test buttons have an obvious reset or unlock position. If it’s physically broken or will not spring back, the socket likely needs replacement. In the field, a temporary workaround for a stuck test button could be gently working it back and forth to release it, but ultimately replacing that relay socket is the sure fix to avoid recurring issues.

When a relay or its base does need replacement, minimizing downtime is key. In some control panels, there may be socket replacement without full downtime by leveraging redundancy. For instance, critical equipment might have two relays in parallel so that one can take over while the other is serviced. In practice, though, most maintenance involves scheduled downtime. To make relay swaps faster, have pre-wired replacement sockets or modules on hand. Label wires on the old socket clearly, then it’s a simple task to move them to the new one. Using blade or plug-in relay modules speeds up replacement – you can pull the faulty relay out of its socket and plug in a new one in seconds (just ensure power is off unless the design explicitly supports hot-swap). Also, consider using guide rails and marking so that even less experienced technicians can quickly identify and replace the correct relay.

For long-term reliability, proactive maintenance and diagnostics go a long way. Diagnostic logging for relay panels is an advanced strategy where you record each relay’s operations and performance. Modern PLCs or control systems can log every time a relay coil is energized or de-energized. By analyzing this log, you might detect a relay that chatters (many rapid on-off events) or is operating far more frequently than expected – a sign of a control issue or impending failure. Some smart relay coils even allow current monitoring; an increasing coil current or slower operate time could indicate wear. Additionally, failed relay detection techniques can be built into the system: for example, using an auxiliary contact on the relay to feed back its status to the PLC. If the PLC commands the relay on but doesn’t see the auxiliary contact change state, it knows the relay failed to actuate (or its contacts failed) and can trigger an alarm. Another technique is measuring the load current – if a relay is turned on but the load draws no current, the relay or load may have failed. There are dedicated relay monitoring modules that measure continuity or voltage on the contacts to immediately detect contact failure or sticking.

In summary, design your system so that it’s easier to troubleshoot: include indicator LEDs (most modern relay sockets have coil indication), consider noise filtering add-ons, and keep spare relays handy. Procurement teams should source high-quality relays from reputable manufacturers to ensure longevity, and automation designers might design in self-test features for critical relays. Meanwhile, maintenance engineers and panel technicians should schedule periodic checks – feel for any abnormal heating, listen for buzzing, and test any manual operators (like test buttons) to ensure they aren’t stuck. By combining good design, regular maintenance, and diagnostic tools, you can drastically reduce unexpected relay failures.

Key Takeaways:

Regularly test and inspect relays and their sockets. Use the built-in test button periodically (with safety procedures) to ensure the relay operates and then fully releases. Replace any socket with a sticking manual operator.

Keep spare relays and sockets readily available. Clearly label and document wiring so that a failed relay can be swapped with minimal downtime. Planning for quick replacement is part of good maintenance practice.

Implement diagnostics for critical relays: use auxiliary contacts or sensors to detect if a relay actually switches as commanded. Logging relay operations helps in predictive maintenance – you can replace a relay nearing the end of its reliable life before it fails.

FAQ

Q: Why is my relay not powering the load?

A: If your relay isn’t powering the load, first check whether the relay coil is energizing (listen for a click or look for an indicator light). If not, the coil may not be getting voltage – causes include a blown fuse, incorrect coil voltage, loose or reversed wiring to the coil, or a bad coil. Verify the control voltage is present at the coil terminals with a multimeter. If the coil is energized (relay clicks) but the load still doesn’t turn on, then the issue is on the output side. Check that the load is wired to the correct relay contacts (common and NO or NC). Also inspect the relay contacts and socket for burns, corrosion, or sticking. A welded or worn-out contact can prevent power from flowing to the load, in which case the relay should be replaced.

Q: What causes relay chatter and how can I fix it?

A: Relay chatter – rapid clicking on and off – is typically caused by the coil voltage dropping out or by electrical noise. Common causes are an unstable power supply, voltage dips when other equipment starts, or interference on the control signal. Essentially, the relay coil isn’t getting a steady enough signal, so it energizes and de-energizes in quick succession. To fix chatter, ensure the coil is driven by a stable voltage above its minimum requirement at all times (you may need a better power supply or to separate the coil circuit from large loads). For DC coils, always use a flyback diode and consider adding a filter capacitor to smooth the supply. If noise or EMI is a factor (e.g. the relay triggers when a nearby device switches), use shielded wiring, install an RC snubber or MOV to absorb spikes, and add proper grounding. These steps will remedy relay chatter by eliminating the transient conditions causing it.

Q: How can I prevent my relay contacts from sticking or welding?

A: Contact sticking (welding) happens when the relay’s contacts fuse together, usually due to high current arcing. To prevent this, make sure you select a relay rated for the maximum and inrush current of your load – for instance, a motor or lamp can draw a surge many times its normal current. Using a relay with a safety margin or one designed for high inrush will greatly reduce welding risk. You can also add protective components across the load: an RC snubber, varistor (MOV), or diode (for DC) will tame the voltage spikes and arcs that occur when contacts open, thus reducing contact wear and welding. Additionally, keep the contacts and socket terminals clean and secure. Heat from a poor connection can deform contacts and contribute to sticking, so tighten screws and replace corroded parts. If a relay’s contacts do weld, it’s best to replace that relay and investigate if a higher-rated or slower-acting relay (or a different switching method) is warranted for the application. Regular inspection and maintenance can catch signs of pitting or burning on contacts before they reach the point of welding.

Conclusion

Relay problems can be a headache, but with systematic troubleshooting you can pinpoint the cause and restore operation quickly. Whether it’s identifying why a relay socket is not powering the load, fixing a relay coil not energizing due to wiring issues, or resolving intermittent chatter, the key is careful observation and following the steps outlined above. Field technicians and maintenance engineers armed with this knowledge – and supported by good design choices from automation designers and proper component selection by procurement teams – can significantly reduce downtime caused by relay failures. Always remember to consider the operating environment and usage conditions: choosing the right relay for the job (with appropriate coil voltage, contact rating, surge protection, etc.) is half the battle in preventing false triggering or premature failures.

If you’re frequently encountering relay issues, it may be time to upgrade to higher quality or more robust relay sockets and relays. We CDGKZ Zhejiang Chuangdao Electric Co., LTD offer a full range of industrial-grade relays and relay sockets with features like LED status indicators, test buttons, and built-in surge suppression to make troubleshooting easier and to prevent common failures. Don’t let a $10 relay be the weak link that stops your production line – get in touch with our team for expert advice on selecting reliable relays, or browse our catalog to find the perfect relay solution for your needs. By investing in better components and following best practices, you can ensure your relays latch and release exactly when they’re supposed to, keeping your operations running smoothly.