Omron Relay Alternatives from China: OEM Options for Buyers

Omron relays have long been synonymous with reliability, yet global buyers increasingly face two major pain points: high costs and extended supply lead times. Engineers and procurement managers are under pressure to find high‑quality replacements that integrate seamlessly into existing designs without sacrificing performance. This article shows how Omron relay alternatives from trusted Chinese manufacturers—particularly CDGKZ—deliver perfect replacements that maintain compatibility while dramatically improving cost efficiency and delivery schedules. With proper sourcing, buyers can gain all the benefits of Omron relays without the downsides, making CDGKZ a compelling partner.

TL;DR

Why replace Omron relays? Rising prices and long supply cycles push buyers to seek Omron relay alternatives and OEM relay socket suppliers.

China’s advantage: Leading Chinese manufacturers provide high‑quality, Omron‑compatible relay bases and sockets that meet CE, UL and RoHS standards while reducing costs.

CDGKZ’s strengths: CDGKZ owns the entire production chain—mold design, injection molding, and test labs—offering OEM/ODM relay solutions that perfectly replace Omron products.

What to consider: Match electrical specifications, ensure certifications and evaluate supplier experience to select the right replacement.

Final takeaway: Switching to CDGKZ’s Omron relay alternatives means getting comparable reliability with lower costs, faster delivery and customization options.

Why Seek Omron Relay Alternatives?

For decades, Omron relays have set the standard for industrial automation, power supplies and control systems. Nevertheless, the global supply landscape has shifted. Buyers routinely face increasing prices, minimum order quantities and lead times spanning weeks or months. A single delayed delivery can stall production lines or raise project costs. Additionally, global OEMs often need to qualify multiple suppliers for risk diversification and supply continuity.

This is where Omron relay alternatives come in. A growing number of engineers look for relays that match Omron’s electrical specifications, pin configurations and form factors but are sourced from manufacturers with better availability and pricing. Choosing China Omron relay replacements or Omron relay equivalent manufacturers helps overcome supply hurdles without compromising quality.

Economic factors also influence the shift. Many Chinese manufacturers operate large, automated facilities that benefit from economies of scale and lower labor costs. As a result, they offer low‑cost Omron relay replacement suppliers capable of meeting demanding international customers. The key is to ensure any replacement meets strict safety standards—both for mechanical integrity and for environmental compliance. North American safety standards focus on preventing fires and require UL or CSA certification, while European standards emphasize insulation distance and tracking resistance. By choosing relays that carry UL, CSA, CE and RoHS certifications, buyers protect end users and comply with local regulations.

Key Takeaways:

High prices and long lead times drive demand for Omron relay alternatives.

Equivalent relays must match coil voltage, contact ratings and mechanical dimensions to ensure drop‑in replacement.

Ensure substitutes meet UL/CSA, CE and RoHS certification requirements to maintain compliance.

Internal Link Suggestion: Learn more about our Omron relay cross‑reference charts to quickly find compatible CDGKZ replacements.

Advantages of Choosing Chinese OEM Relay Manufacturers

China’s relay industry has grown rapidly over the last decade. Investments in research and development, advanced precision stamping and dedicated industrial parks have elevated Chinese manufacturers’ capabilities. According to industry analyses, leading Chinese relay companies emphasize quality assurance and environmental responsibility, maintaining strict quality control protocols and adhering to ISO and RoHS standards. This means that buyers no longer need to compromise on quality when selecting a China Omron relay replacement.

Competitive Pricing and Production Efficiency

Thanks to large production volumes and efficient manufacturing techniques, Chinese OEM manufacturers can offer cost‑effective Omron relay sockets at prices substantially lower than those of Japanese or Western brands. For example, the economies of scale realized in industrial parks allow for optimized material procurement, automated assembly lines and continuous improvements in yield. This translates to competitive unit costs and the ability to handle high‑mix, low‑volume orders—a perfect fit for OEM/ODM customers seeking customization.

Comprehensive Certification and Environmental Compliance

Top Chinese relay manufacturers, including CDGKZ, invest heavily in compliance. Their products are certified by UL, CE and TÜV, and they also comply with ISO9001 quality standards. More importantly, they adhere to RoHS directives, which restrict hazardous substances like lead, mercury, cadmium and hexavalent chromium in electrical and electronic equipment. RoHS 3 (Directive 2015/863) further prohibits DEHP, BBP, DBP and DIBP, ensuring the relays are safe and environmentally friendly.

Diverse Product Range and Rapid Innovation

Chinese manufacturers supply a wide range of relay types, including power relays, solid‑state relays, electromagnetic relays and relay sockets. For instance, industry leaders like Shenler offer general relay sockets, DIN‑rail mount models and PCB‑mounted versions, all with UL, CE, TUV and ISO9001 certification. This diversity makes it easy to find Omron relay socket alternatives that match specific application requirements, such as contact configuration, pin count or mounting style.

Key Takeaways:

Chinese manufacturers offer competitive pricing and flexible MOQs for Omron relay alternatives.

Products often carry UL/CE/TUV certifications and comply with RoHS and ISO9001electroniccomponent.comcertification-company.com.

A broad product portfolio allows easy sourcing of compatible relays and sockets.

Internal Link Suggestion: Explore our OEM relay manufacturing capabilities for details on custom designs, injection molding and quality testing.

How CDGKZ Provides Perfect Omron Relay Alternatives

CDGKZ stands out among Chinese relay manufacturers by controlling every step of the production process—from mold design to final testing. This vertical integration ensures that CDGKZ relays and sockets meet the precise requirements of Omron products, making them ideal Omron relay replacement options in China.

Design and Engineering Capabilities

Our engineering team reverse‑engineers Omron products to understand their electrical and mechanical specifications. We then design Omron‑compatible relay bases and sockets that mirror pin configuration, PCB footprint and mounting dimensions. CAD‑to‑mold integration shortens the development cycle, and in‑house toolmaking ensures accuracy. Because we control the design, we can quickly modify products for custom coil voltages, contact arrangements or housing materials—an advantage not possible with off‑the‑shelf solutions.

In‑House Manufacturing and Quality Control

CDGKZ operates a fully automated injection molding workshop, metal stamping lines and assembly stations. Our OEM relay socket manufacturing in China uses high‑precision molds to produce housings with tight tolerances, resulting in stable contact pressure and reliable electrical performance. Each product undergoes 100% functional testing, including contact resistance, dielectric strength, coil resistance and mechanical endurance. This rigorous process ensures that our Omron relay OEM solutions match the performance of the original components.

To guarantee compliance, our products are tested for adherence to UL and CSA standards (fire safety, ignition performance and temperature risecomponents.omron.com), EN/IEC standards (insulation distance and tracking resistancecomponents.omron.com) and RoHS restrictions on hazardous substancescertification-company.com. We provide certificates and test reports with every shipment.

Customization and OEM/ODM Services

Because CDGKZ is an Omron relay OEM/ODM manufacturer, we can tailor products to meet specific customer needs. Need a specialized socket for a high‑ambient‑temperature environment? We can change the housing material. Require a different coil voltage or contact rating? We can redesign the coil and contact system. We also offer labeling and packaging services, enabling customers to brand the products under their own names. Importantly, our lead times are shorter because we have control over the supply chain. Buyers get the reliability of Omron with the flexibility and cost savings of an OEM partner.

Key Takeaways:

CDGKZ designs and manufactures Omron‑compatible relay bases in‑house, enabling quick customization.

Strict quality control ensures compliance with UL/CSA, EN/IEC and RoHS standard

OEM/ODM services offer tailored solutions and branding opportunities.

Internal Link Suggestion: Check our product categories page to browse standard and customized relay sockets for every application.

Selecting the Right Omron Relay Replacement: Key Considerations

Identifying the right Omron relay compatible OEM factory requires careful attention to specifications and quality. Here are the main factors to consider:

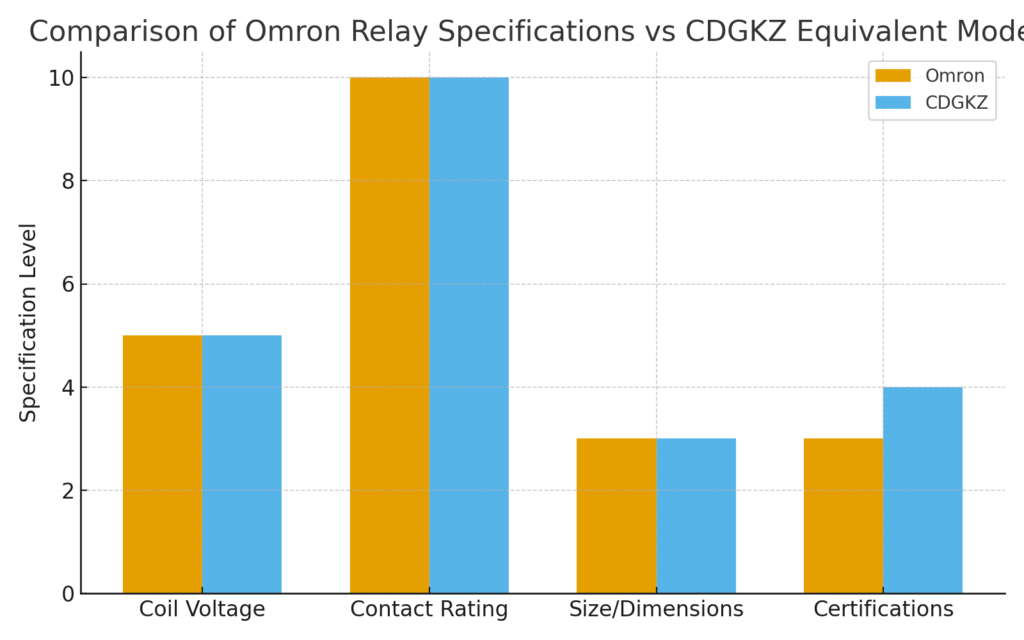

Electrical Specifications – Ensure the coil voltage (e.g., 5 Vdc, 24 Vdc) and contact ratings (current and voltage) match the original Omron relay. Mismatched ratings can lead to coil burnout, contact welding or premature failure.

Contact Configuration & Pin Layout – Verify that the replacement has the same contact arrangement (SPST, SPDT, DPDT, etc.) and that the pins align with the original relay socket or PCB layout. Manufacturers like CDGKZ provide cross‑reference tables to help match part numbers.

Mounting Type & Housing – Omron relays come in plug‑in, DIN‑rail and PCB‑mount styles. Make sure your alternative is compatible with the existing mounting method. For DIN‑rail applications, look for Omron compatible DIN rail relay sockets with secure locking mechanisms and integrated jumpers.

Certifications & Compliance – Check for UL, CSA, CE and RoHS compliance marks. North American and European standards differ in their focus on fire safety and insulation distancescomponents.omron.com, while RoHS restricts hazardous substances. Certified replacements guarantee safety and legal compliance.

Supplier Reliability – Choose manufacturers with proven track records, adequate production capacity and responsive technical support. Leaders like CDGKZ, Shenler and other Chinese suppliers emphasize ISO‑certified quality systems and environmental responsibility

Key Takeaways:

Match coil voltage, contact ratings and pin layout to ensure drop‑in compatibility.

Choose products certified by UL/CSA, CE and RoHS.

Evaluate supplier experience, manufacturing capacity and service.

Internal Link Suggestion: Need help matching specifications? Visit our relay selection guide for step‑by‑step advice.

Tips for Working with OEM Partners in China

Collaborating with an OEM supplier in China can be immensely rewarding, but success requires clear communication and careful vetting. Here are some best practices to follow when sourcing Omron relay alternatives for automation:

Verify Certifications and Audits

Before placing an order, request copies of the supplier’s UL, CE and RoHS certificates. Check that the product categories match your application. If possible, perform a factory audit or ask for a video tour to verify the production environment and quality control procedures. Leading manufacturers emphasize complete compliance, with dedicated teams overseeing documentation and product testing.

Request Samples and Test Prototypes

Ask for sample units of the Omron relay replacement options in China you intend to purchase. Test them for electrical performance, mechanical fit and thermal behavior under your application’s conditions. Prototyping ensures that the replacements will operate reliably once scaled up.

Discuss Customization Early

OEM/ODM suppliers are flexible but require clear specifications. Share details like coil voltage, contact configuration, expected mechanical life and operating environment. Provide drawings or reference models when possible. Early collaboration reduces design iterations and accelerates time‑to‑market.

Protect Intellectual Property and Agreements

Ensure that your purchase agreements include confidentiality clauses, quality standards and penalty terms for non‑compliance. A well‑structured contract protects both parties and fosters long‑term relationships.

Key Takeaways:

Validate suppliers’ certification documents and quality processes.

Use samples and prototypes to confirm fit and performance.

Provide clear specifications and protect contractual interests.

Internal Link Suggestion: Learn more about our OEM partnership process for a step‑by‑step overview of collaboration with CDGKZ.

FAQ

Q1: How can I be sure CDGKZ relays are fully compatible with Omron relays?

A: CDGKZ designs its Omron relay socket alternatives by matching the pin configuration, contact ratings and mounting style of the corresponding Omron models. Each product is tested for electrical performance and mechanical fit. We also provide cross‑reference tables and samples to verify compatibility before you place large orders. If you need customization, we can adjust coil voltage or contact arrangement while maintaining overall dimensions.

Q2: Do CDGKZ products meet international safety and environmental standards?

A: Yes. Our products are certified to UL and CSA standards, ensuring fire and electrical safety for North America, and to CE/EN/IEC standards for European marketscomponents.omron.com. We also adhere to RoHS directives, which restrict hazardous substances like lead, mercury and cadmium in electrical equipmentcertification-company.com. Certificates and test reports are supplied upon request.

Q3: What makes CDGKZ a better choice than other Chinese manufacturers?

A: CDGKZ owns its mold design, injection molding, assembly and testing facilities, which allows us to control quality and delivery time. We provide OEM/ODM services with short lead times, support small and large orders and offer product customization. Our strong focus on compliance (UL/CE/TÜV/ISO/RoHS) and our experienced engineering team make us a reliable partner for engineers seeking Omron relay alternatives.

Conclusion & Call to Action

Rising costs and unpredictable lead times push engineers and procurement managers to look for Omron relay alternatives. Chinese OEM manufacturers—especially CDGKZ—provide high‑quality relay bases and sockets that are fully compatible with Omron products while offering competitive pricing, faster delivery and the flexibility of OEM/ODM customization. With certifications covering UL, CE, CSA and RoHS, these products satisfy international safety and environmental requirements.

Choosing CDGKZ means partnering with a manufacturer that controls every step of production, from mold design to final testing. We deliver reliable replacements that help customers maintain performance, reduce costs and secure supply chains. Ready to upgrade? Contact CDGKZ today to discuss your project or request a sample, and discover how our Omron relay alternatives for automation can elevate your designs. Don’t let supply shortages or high prices slow you down—switch to CDGKZ and experience the best of both worlds.