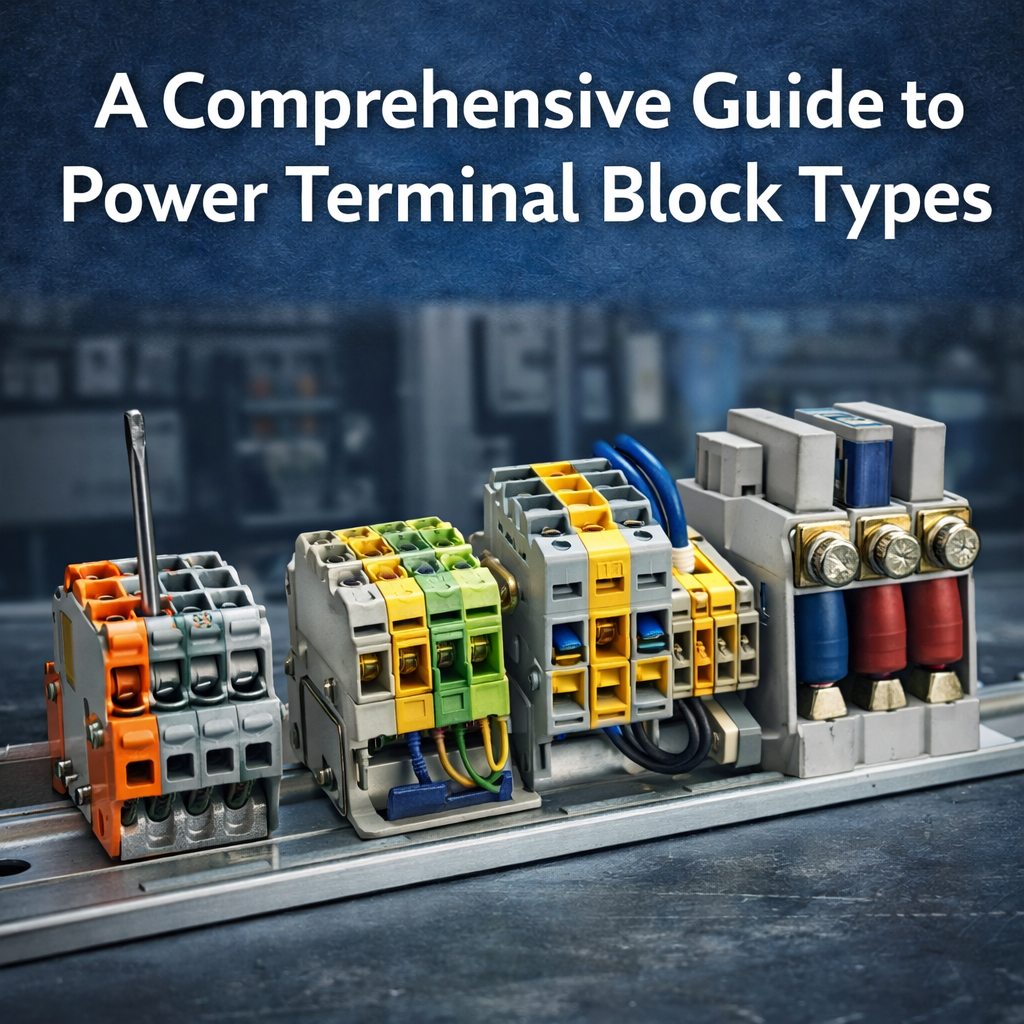

A Comprehensive Guide to Power Terminal Block Types – Covering Industrial Terminal Blocks and DIN Rail Terminal Block Systems

From control panels to factory automation, engineers often struggle to select the right industrial terminal block for each application. With multiple power terminal block types – from traditional screw terminals to newer spring-clamp and push-in styles – plus varying current/voltage ratings and standards, the choice can be daunting. This guide clarifies DIN rail terminal block options, helping you design safer, more cost-effective electrical systems that meet industrial demands.

TL;DR

- Multiple Connection Types: Screw-type terminal blocks offer tried-and-true clamping for robust connections, spring-clamp and push-in terminal blocks enable faster, tool-free wiring. Each has pros/cons for different needs.

- Electrical Ratings Matter: Always choose terminal blocks with suitable current and voltage ratings. High-current designs often use larger screw or bolt clamps, and a safety margin (e.g. 150% of max load) is wise.

- Application-Specific Choices: For control panels and electrical cabinets, modular DIN rail blocks organize wiring neatly. In high-vibration or automated systems, spring or push-in terminals shine, whereas screw/bolt types handle heavy power distribution.

- Standards & Quality: Opt for UL-listed/CE-marked terminal blocks to ensure compliance and safety. Industrial blocks meeting UL 1059 and IEC 60947-7-1 standards have been tested for fire resistance, insulation, and durability.

Types of Power Terminal Blocks: Screw-Type, Spring-Clamp, Push-In, and More

Power terminal blocks come in various designs to secure electrical conductors. The most common is the screw type terminal block, where a screw tightens a clamp onto the wire. Screw terminals are widely used due to their reliable mechanical connection and versatility across wire sizes. They are time-tested for industrial terminal blocks and can handle moderate to high currents, but require a screwdriver and proper torque during installation. Over time or in vibrating machinery, screws may loosen if not periodically checked.

By contrast, spring clamp terminal blocks (including push-button and tension spring variants) use a metal spring mechanism to grip the wire. Inserting a wire compresses the spring, which then applies continuous pressure. This ensures the connection resists loosening from vibration. Spring-clamp terminals allow quicker installs (no tightening torque needed) and provide maintenance-free service, making them ideal for control systems subject to shock or movement. Push-in terminal blocks are a refinement of the spring concept: a solid or ferruled wire is simply pushed straight into the terminal hole, where an internal spring-cage locks it. No tools are required to terminate, greatly speeding up wiring. Push-in designs are popular in high-volume panel assembly and PLC wiring, though they typically suit small-to-medium wire sizes.

Other specialty types include barrier terminal blocks and bolt-down terminals. Barrier strips use screws and barriers (often with ring lugs) to provide secure, segregated connections – common in higher-power or legacy systems. Bolt or stud terminals feature a bolt and nut to clamp very large conductors or busbars, supporting the highest currents and withstanding harsh environments. These are found in heavy-duty power distribution blocks. Overall, each terminal style balances ease of use, contact force, and current capacity. Understanding these differences helps in selecting the optimal connector for your project’s needs.

| Type | Installation Speed | Vibration Resistance | Current Capacity | Typical Applications |

|---|---|---|---|---|

| Screw Terminal Block | Medium | Medium (retightening required) | Medium-High | Control panels, power distribution |

| Spring Clamp Terminal Block | Fast | High | Low-Medium | Automation, PLC I/O, machinery |

| Push-In Terminal Block | Very Fast | High | Low-Medium | Mass wiring, signal circuits |

| Bolt / Barrier Block | Slow | Very High | Very High | Main feeds, busbars, heavy power |

Key Takeaways:

– Screw terminals offer strong, reliable connections for a wide range of wire sizes but require manual tightening and periodic checks.

– Spring-clamp and push-in terminals enable faster, tool-free wiring and resist vibration-related loosening, ideal for frequent re-wiring or high-vibration settings.

– High-current needs may demand bolt-type or barrier blocks, which accommodate larger conductors and provide maximum stability.

Learn more: Explore CDGKZ’s full range of DIN rail terminal blocks to find screw, spring and push-in models for your application.

Designing for High Current: Terminal Block Current and Voltage Ratings

When dealing with power distribution, the design of a high current terminal block must safely carry heavy loads without overheating or voltage breakdown. Manufacturers specify a terminal block’s current rating based on testing (often at a standard ambient temperature, e.g. 20°C). This rating indicates the maximum continuous current the terminal can carry. As a rule of thumb, you should select a terminal with a current rating comfortably above your circuit’s maximum load. For instance, if a circuit draws 10 A, a terminal rated for 15 A or more (150% of the load) provides a safety margin. This accommodates surges or inrush currents and prolongs the connector’s life. Exceeding a terminal’s rating risks excessive heating at the contact point, which can lead to insulation damage or fire.

Terminal block voltage rating is equally important. It defines the highest circuit voltage the block’s insulation and spacing can withstand. Common industrial terminal blocks are rated for 300 V or 600 V (AC/DC) in North America (per UL standards), and up to 800–1000 V under IEC standards for certain designs. Always use a terminal block with a voltage rating at or above your system’s maximum voltage. Higher ratings ensure adequate insulation thickness and creepage distances between conductive parts. For example, a DIN rail terminal meeting IEC 60947-7-1 might be rated 1000 V, suitable for solar photovoltaic combiner boxes or multi-motor panels.

High-current terminal blocks often incorporate features to handle stress. They may use larger cross-section metal bodies (e.g. copper alloy clamps), screws with higher torque capacity, or dual clamping points to distribute force. Bolt-type terminal blocks are common for currents above ~100 A, where a screw or hex bolt tightly compresses the conductor lug against a busbar. This provides a very robust connection for main power feeds. Additionally, such blocks and power distribution terminal block units have heavy-duty contacts to withstand vibration and surge loads. Always observe the manufacturer’s guidelines on stripping length and tightening torque for these connectors – improper installation can reduce the effective rating. Finally, remember that ratings can diminish in higher ambient temperatures; if your panel runs hot, choose a higher-rated terminal or derate accordingly to maintain safety.

Key Takeaways:

– Choose ample capacity: Select terminal blocks with a current rating above your maximum operating current (ideally ~150% of expected load) to avoid overheating.

– Match or exceed voltage needs: Ensure the terminal’s voltage rating meets or surpasses your system voltage. E.g. use 600 V-rated blocks on 480 V circuits for safe insulation.

– High-current designs: For large currents, look to bolt-clamp or heavy-duty terminals. They use robust metal components and secure fastening to handle high amps and mechanical stress.

Learn more: See our Terminal Block Technical Specifications Explained guide for a detailed look at current, voltage, and wiring specs in industrial terminals.

Application Scenarios: Control Panels, Power Distribution, and Automation

Different applications call for different terminal block solutions. In control panels and electrical cabinets, modular DIN rail terminal blocks are the backbone of wiring organization. These blocks snap onto standard rails (like 35 mm DIN rails) and neatly connect incoming and outgoing wires. For example, an industrial control cabinet may use dozens of feed-through terminals to distribute power and signals to various devices. The advantages are clear: labeling and color-coding of terminal blocks make maintenance easier, and adding or removing a circuit is as simple as clipping another block onto the rail. Terminal blocks for control panels are typically screw or push-in type, handling anything from low-voltage sensor wires to mains supply lines in a structured manner.

For power distribution, specialized high-current terminal blocks (often called distribution blocks or busbar terminals) are used to split a single supply into multiple circuits. A power distribution terminal block might take a large gauge feed (e.g. from a transformer or battery bank) and provide several smaller outputs, each secured by screw or bolt clamps. These blocks often have protective covers and are designed for safe splicing of heavy amperage circuits, such as in motor control centers or power backup systems. They must be mounted securely due to the weight and stiffness of thick conductors. Distribution terminal blocks greatly simplify wiring by eliminating a “star” of spliced cables; instead, one input feeds into a block that outputs to many branches.

In automation systems and machinery, the emphasis is on vibration resistance and serviceability. Terminal blocks for automation systems (e.g. PLC I/O racks, robotics controllers) often favor spring-clamp or push-in connections. Because machines may generate constant motion or require frequent module swaps, the maintenance-free nature of spring terminals is valued – they won’t shake loose and technicians can rewire sensors or actuators quickly without screws. For instance, a packaging line control box might use push-in terminals for all the sensor inputs, significantly cutting down wiring time and ensuring reliable connections despite machine vibrations.

Environmental factors also play a role. In marine or chemical factory environments, terminal blocks might need corrosion-resistant materials or IP20 finger-safe covers. Terminal blocks for electrical cabinets that are outdoors (like traffic signal controllers or solar inverters) may require enclosed, waterproof terminals or at least those that maintain clamping force through temperature swings. Additionally, grounding terminals (often green/yellow) are used on DIN rails to bond circuits to the panel ground – these clamp the wire and mechanically connect to the metal DIN rail, forming a common earth bus.

Key Takeaways:

– Control panels: DIN rail terminal blocks enable compact, organized wiring in control panels and cabinets. They simplify troubleshooting and modifications in complex industrial systems.

– Power distribution: High-current distribution blocks safely split main power feeds into sub-circuits, using robust screw/bolt clamps to handle large cables and amperages.

– Automation: Spring-clamp and push-in blocks thrive in automation and machinery due to vibration-proof, quick-connect wiring – minimizing downtime in high-motion or frequently serviced equipment.

Learn more: For a step-by-step look at installing and wiring DIN rail blocks in control panels, see our Terminal Block Installation & Wiring Guide for best practices.

Terminal Block Selection Guide: Screw vs Spring and How to Choose

Selecting the right terminal block comes down to balancing technical requirements with practical considerations. A common debate is screw vs spring terminal block connections – each excels in different aspects. To decide, first evaluate your application’s electrical needs: How to choose a power terminal block starts with current and voltage. If you have high-current conductors (e.g. feeding a motor or breaker), screw-clamp or bolt terminals are often preferable because they typically support larger wire gauges and provide the high clamping force needed for a low-resistance contact. For example, a 50 A circuit might be best served by a screw terminal rated for 600 V/100 A, rather than a push-in terminal that tops out at 20–30 A. On the other hand, for low-voltage control wiring (24 V PLC signals, 4–20 mA sensors), a push-in or spring terminal block can save enormous installation time and require no tools – an important factor in large-scale projects with thousands of connections.

Next, consider the environment and maintenance. In a stable environment (little vibration, infrequent rewiring), traditional screw terminals work reliably, provided they are tightened correctly. However, if the equipment is subject to constant vibration or if connections will be changed regularly, spring terminals offer a clear advantage by maintaining tension automatically. They won’t back off due to vibration, and wires can be reterminated easily without worrying about torque. Also think about space and density: push-in terminals often have a more compact design, allowing higher packing density on a DIN rail – useful when panel space is at a premium.

Another selection factor is the skill level of personnel and available tools. Spring and push-in blocks reduce the chance of installation error (no under- or over-tightening screws). They can be more cost-effective in terms of labor: assembly can be 50% faster, which cuts installation cost. Screw terminals, conversely, require a torque screwdriver for optimal results and periodic tightening during maintenance shutdowns. In terms of upfront cost per piece, screw types are usually very affordable, while advanced push-in blocks might be slightly higher priced – but this often pays off in labor savings.

Finally, ensure any terminal block you choose fits the compliance needs of your project (more on this below). If your assembly must meet UL or IEC standards, use recognized components accordingly. Often the manufacturer’s terminal block selection guide or datasheet will list applicable standards and ratings – use this information to narrow choices. In summary, there is no one-size-fits-all: the “best” terminal block is the one that matches your electrical specs, environmental conditions, and workflow requirements.

Key Takeaways:

– Screw vs spring: Use screw terminals for high currents and where maximum pull-out strength is needed; use spring/push-in terminals for faster installation and vibration resistance in lighter-duty or signal wiring.

– Selection factors: Match the terminal’s ratings to your circuit (current, voltage, wire size) and consider environment (vibration, temperature) plus maintenance needs when choosing.

– Efficiency vs upkeep: Spring and push-in blocks minimize installation time and maintenance, whereas screw blocks may require retightening but are very versatile and typically lower cost per unit.

Learn more: Check out our Terminal Block Selection Guide 2026 for a detailed checklist on choosing the right terminal block for any project step by step.

Standards and Quality: UL, IEC, and Certifications

In industrial settings, using certified, high-quality components is critical for safety and compliance. UL certified terminal blocks are essential for equipment destined for North America. Underwriters Laboratories (UL) Standard 1059 governs terminal blocks as recognized components in industrial control equipment. A UL-listed or UL-recognized terminal block has passed tests for dielectric strength, heat resistance, and flammability. For example, UL 1059 requires a terminal block’s insulating body to meet UL94 V-0 flame retardancy (self-extinguishing with no burning drips) and mandates sufficient creepage distance for the rated voltage. Using UL-recognized terminals in a UL 508A control panel can simplify the panel’s approval process. In practice, look for the “UR” mark or UL logo on terminal block datasheets – it indicates the product adheres to those safety standards. As one guide advises, for industrial use you should look for UL and IEC certifications on terminal blocks to ensure global compliance.

Globally, the IEC terminal block standards provide a benchmark for performance. IEC 60947-7-1 (and 60947-7-2 for fuse terminals) is the key standard covering low-voltage terminal blocks, particularly the feed-through and ground terminals mounted on DIN rails. An IEC-certified terminal block will have undergone rigorous testing for mechanical durability, electrical conductivity, and temperature rise at rated current. For instance, IEC 60947-7-1:2009 (updated in 2025) specifies that a terminal must endure vibration tests and still maintain contact integrity, and outlines how current and thermal limits are verified. In Europe, compliance with IEC/EN 60947 is often required to obtain the CE marking on industrial control assemblies. Thus, reputable manufacturers design their products to meet both UL and IEC criteria, ensuring that an industrial terminal block can be used in installations worldwide without issue.

Beyond UL and IEC, other certifications boost confidence in a terminal block’s quality. The CE mark indicates conformity with EU directives like the Low Voltage Directive (safety requirements) and RoHS (hazardous substances restrictions). Many industrial buyers also check for CSA certification (for Canada, analogous to UL), and adherence to IEC 60947-7-1 means the product likely also meets related standards like IEC 60947-7-2 (for distribution blocks) or IEC 60204 (safety of machinery electrical components). Environmental and material certifications are important too: RoHS compliance (no lead or other heavy metals in the materials) and REACH compliance ensure the terminal block is not only safe electrically but also environmentally. Ultimately, choosing terminal blocks that carry these approvals is choosing proven reliability. It provides peace of mind that the connector won’t be the weak link in your system and that using them keeps your project in line with regulatory requirements.

| Standard | Region | What It Ensures | Why It Matters |

|---|---|---|---|

| UL 1059 | North America | Fire resistance, insulation strength | Required for UL508A industrial control panels |

| IEC 60947-7-1 | Global / Europe | Thermal rise limits, vibration resistance, mechanical durability | International acceptance for industrial terminal blocks |

| CE Mark | European Union | Conformity with EU safety and EMC directives | Legal requirement for access to the EU market |

| RoHS / REACH | Global | Restriction of hazardous substances and chemical safety compliance | Ensures environmentally safe and legally compliant materials |

Key Takeaways:

– UL 1059 compliance: UL-certified terminal blocks have passed strict tests (insulation, flame retardance, etc.) and are required for many North American industrial panels – look for UL Recognized marks to ensure compliance.

– IEC standards: IEC 60947-7-1 is the international standard for DIN rail terminal blocks (up to 1000 V); using IEC-rated blocks means they’ve met global safety and performance benchmarks.

– Quality marks: Certifications like CE (EU safety directives), CSA (Canada), and RoHS indicate a terminal block meets high quality, safety, and environmental standards, which is vital for trust in critical applications.

Learn more: See how CDGKZ terminal blocks achieve UL, CE, RoHS, and IEC certifications in our compliance guide, ensuring they meet all major industry standards.

FAQ

Q1: What are the main types of power terminal blocks and their uses?

A: The primary types of power terminal blocks are screw-clamp, spring-clamp, and push-in. Screw-clamp terminals use a screw to tighten the wire and are common in many applications for their strong connection and high current capacity. Spring-clamp terminals use a spring mechanism to hold the wire, offering quick installation and vibration resistance – great for machinery and automation. Push-in terminals allow you to insert a wire without tools, ideal for fast assembly in control panels (typically for smaller wires or signal lines). Additionally, there are barrier terminal blocks (with screws and insulating barriers, used for higher power isolation) and bolt-type blocks for very high-current or industrial power distribution needs.

Q2: How do I choose between screw-type vs spring-type terminal blocks?

A: It depends on your project’s requirements. Screw-type terminal blocks are preferred for higher currents, larger wire sizes, and when you need the absolute tightest connection – for example in power distribution or where periodic maintenance (retightening) is feasible. They’re very reliable but slower to install. Spring-type (including push-in) terminal blocks excel in environments with vibration or when you have many repetitive connections, like mass wiring in control systems. They maintain tension automatically (no loose screws) and significantly speed up installation. If your priority is quick, error-free wiring and low maintenance, go with spring or push-in. If you need maximum clamping force and don’t mind using tools, screw terminals are a solid choice. In many panels, engineers actually use both: spring terminals for control wiring and screw terminals for incoming power feeds.

Q3: Why are UL and IEC certifications important for terminal blocks?

A: Certifications are a quick way to know the terminal block meets safety and performance standards. UL certification (North America) means the block has been tested for things like electrical insulation, heat resistance, and safe use up to a certain voltage/current. It’s often legally required for panels that must be UL approved. IEC certification (international/Europe) indicates compliance with standards like IEC 60947, assuring the terminal block will perform under global industrial conditions (voltage, current, mechanical stress) and is likely acceptable to inspectors worldwide. Using UL-certified, IEC-compliant terminal blocks thus helps ensure your electrical system is safe, avoids component failure, and smooths the approval process for your equipment. In short, these marks signify that an independent authority has validated the terminal block’s quality and you can trust it in your design.

Conclusion

Choosing the right terminal block is crucial to the safety and efficiency of any industrial electrical project. By understanding the differences between connection types (screw vs spring vs push-in), evaluating your current and voltage requirements, and ensuring compliance with UL/IEC standards, you can make an informed selection. High-quality, certified terminal blocks will minimize downtime and maintenance in the long run, proving to be cost-effective solutions. As a dedicated terminal block manufacturer, CDGKZ offers OEM DIN rail terminal blocks that meet international standards and suit a wide range of applications – from control panels to power distribution. Contact us for expert guidance or to request a quote on reliable terminal block solutions tailored to your needs.