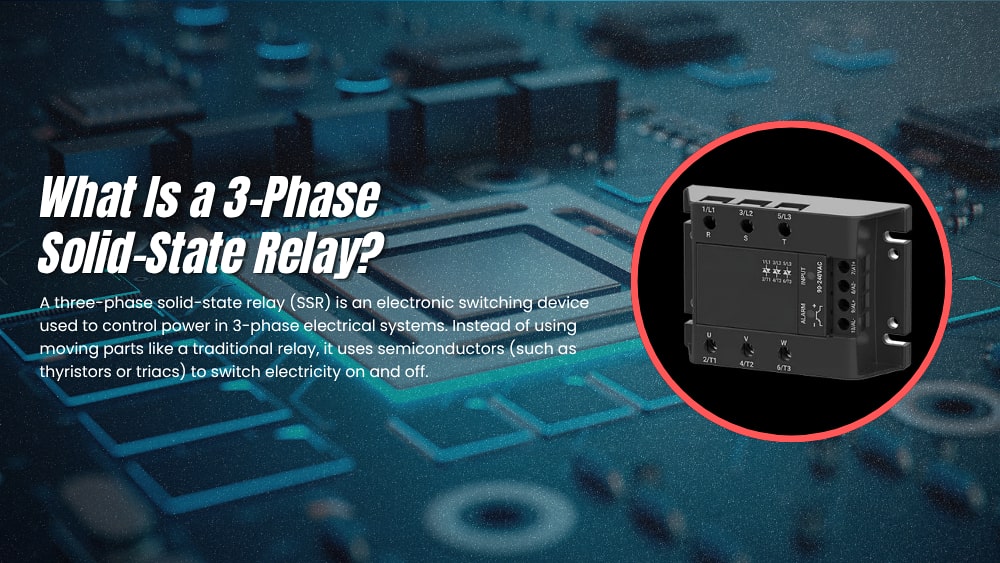

What Is a Three-Phase Solid-State Relay?

A three-phase solid-state relay (SSR) is an electronic switching device used to control power in 3-phase electrical systems. Instead of using moving parts like a traditional relay, it uses semiconductors (such as thyristors or triacs) to switch electricity on and off.

This type of relay is designed for applications that need to control three separate electrical lines at the same time — for example, motors, heaters, or industrial machines that run on three-phase power.

Because it has no mechanical contacts, a three-phase SSR offers several advantages:

Longer lifespan — no wear and tear from moving parts.

Fast switching speed — it can turn on and off very quickly.

Silent operation — no clicking noise like mechanical relays.

Better reliability — works well in dusty or vibrating environments.

In short, a three-phase solid-state relay is a durable and efficient way to control large electrical loads safely and precisely in industrial systems.

Why Do We Need to Use It, And What Is Its Purpose?

Imagine a situation: a large industrial oven needs three heating elements to work simultaneously to raise the temperature. If you use three separate single-phase solid-state relays, the wiring becomes complicated and the heating may not be perfectly synchronized. A three-phase solid-state relay solves this problem perfectly. It integrates three independent switching channels inside and can use a very small control signal (such as a PLC output of DC 3–32V) to synchronously and precisely control the on/off of three powerful AC lines (like 380V AC).

It’s like a “traffic commander” controlled by a smart signal. With just one whistle (the small control signal), it can simultaneously and accurately direct the flow of cars (current) on three lanes (three-phase power) to go (power on) or stop (power off), avoiding the possible inconsistencies that could happen if you had three separate traffic cops (three single-phase relays).

Main Uses and Application Scenarios of 3-Phase SSR Relay

Three-phase solid-state relays (SSRs) are specially designed for industrial situations that require control of high-power three-phase equipment.

1. Controlling Three-Phase Heating Systems

Typical Applications: Industrial electric furnaces, ovens, injection molding machine heaters, hot air units.

Why SSRs Are Used: Heating elements are usually balanced three-phase loads that need to be switched on and off simultaneously to maintain even heating. By adjusting the on/off time ratio (PWM control), SSRs can provide precise temperature regulation.

2. Controlling Three-Phase Motors

Typical Applications: Fans, water pumps, compressors, and other motors requiring soft start or soft stop.

Why SSRs Are Used: Acting as a contactless switch between the motor and power supply, a three-phase SSR can smoothly start or stop motors, reducing impact on the electrical network and mechanical components. However, they are generally not used for frequent speed or direction changes, which are handled by variable frequency drives (VFDs).

3. Controlling Three-Phase Transformer Loads

Typical Applications: Electrochemical equipment, power regulation systems, and other industrial loads connected to transformers.

Why SSRs Are Used: They provide precise, reliable switching of large transformer loads without the wear and tear associated with mechanical relays, improving system stability and safety.

What Are the Differences Between This and a Traditional Three-Phase Contactor (Mechanical Type)?

| Feature | 3-Phase Solid-State Relay (SSR) | Traditional Three-Phase Contactor (Mechanical) |

| Operating Principle | Semiconductor switching (no contacts) | Electromagnetic switching (mechanical contacts) |

| Lifespan | Extremely long, up to hundreds of millions of cycles | Limited, mechanical and electrical wear (usually hundreds of thousands to millions of cycles) |

| Switching Speed | Very fast (milliseconds or even microseconds) | Slower (tens of milliseconds) |

| Noise | Silent | Clicking sound during switching |

| Vibration/Shock Resistance | Strong | Moderate |

| Safety | No sparks, good explosion protection | Contact opening/closing generates arcs |

| Drawbacks | Higher cost, requires heat dissipation, small leakage current | Lower cost, no heat dissipation needed, fully isolated |

In short, you should consider using three-phase solid-state relays when your equipment needs to meet the following conditions:

Load: Three-phase high-power electrical appliances (heating elements, motors, etc.)

Requirements: High-frequency switching, ultra-long lifespan, absolute silence, high reliability, and shock resistance.

It is the ideal choice for achieving precise, efficient, and reliable power control in modern industrial automation.

Do You Need a 30a~100a Three-Phase Solid-State Relay?

3-Phase Solid-State Relay 30 Amp 3-Phase Solid-State Relay 40 Amp 3-Phase Solid-State Relay 50 Amp 3-Phase Solid-State Relay 60 Amp 3-Phase Solid-State Relay 100 Amp