Make in India Relay Manufacturing with CDGKZ: Low-Cost Relay & Socket Solutions from China

The “Make in India” relay manufacturing initiative has spurred local production in electronics, but setting up a new relay and relay socket factory from scratch can be daunting. High capital investment, limited technical know-how, and an unestablished supply chain are major pain points. CDGKZ Made in India solutions tackle these challenges by leveraging China’s mature relay industry. As a leading relay OEM/ODM manufacturer in China, CDGKZ offers India relay socket factory solutions – providing molds, raw materials, and technology transfer – enabling Indian companies to launch low-cost relay production with international quality. This guide explores how partnering with CDGKZ helps localize relay manufacturing in India quickly and affordably, effectively creating a China-to-India relay supply chain for cost-effective relay base factory setup.

TL;DR Highlights:

Local Manufacturing Push: India’s government encourages domestic production of industrial components (relays, sockets) via Make in India, yet new factories face high costs and skill gaps.

China-to-India Supply Chain: Partnering with a Chinese relay supplier like CDGKZ provides ready designs, relay raw materials supplier support, and economies of scale. This drastically lowers the relay factory investment in India, making affordable relay socket production in India possible.

OEM/ODM Partnership: CDGKZ acts as an India relay socket manufacturing partner, offering OEM production of parts and relay socket technology transfer. Indian firms assemble locally, achieving “CDGKZ Made in India” products without heavy R&D.

Global Quality Compliance: Despite the low cost, quality isn’t compromised. CDGKZ’s designs meet CE, UL, and RoHS compliance standards, so relay & socket products assembled in India can carry international certifications

Understanding India’s Relay Manufacturing Challenge

India’s booming industrial and automotive sectors drive growing demand for relays and relay sockets (the bases into which relays plug, also called relay bases). The government’s Make in India program explicitly aims to boost domestic manufacturing across sectors. For Indian companies, this presents an opportunity to produce relays and sockets locally, reducing reliance on imports. However, establishing a relay manufacturing plant involves steep hurdles: acquiring production machinery and molds, developing technical expertise for precision electromechanical assembly, and securing a reliable supply of specialized components. All these factors contribute to high upfront costs and risks for newcomers.

User Pain Point: Many Indian entrepreneurs and firms find that relay factory investment in India is prohibitively expensive when attempted alone. Design and tooling for quality relay sockets require significant R&D. Moreover, sourcing critical parts like copper coils, contact materials, and flame-retardant housings can be challenging without an existing supplier network. This often forces businesses to continue importing finished relays, which contradicts the spirit of Make in India and results in lost local value-add. The need of the hour is a way to bridge the technology and supply chain gap so that Indian companies can domestically assemble relays with minimal barriers.

Opportunity via Partnerships: Rather than building capability from scratch, Indian manufacturers can collaborate with established foreign experts. By leveraging a relay technology partnership (China–India), companies can obtain the know-how and parts needed to kickstart local production. This collaborative approach aligns perfectly with Make in India’s vision of facilitating investment and innovation through global partnerships. It allows Indian firms to own and operate “Made in India” production lines, while minimizing risk through external support.

Key Takeaways:

India’s policy environment favors local manufacturing of components like relays, but cost and expertise barriers are high for solo ventures.

Partnering with an experienced relay manufacturer can fill knowledge gaps and supply chain needs, reducing startup costs dramatically.

Strategic OEM partnerships offer a viable path to achieve Make in India relay manufacturing without reinventing the wheel.

Learn more: Understanding Make in India Initiative (overview of India’s manufacturing incentives)

China-to-India Supply Chain: The Low-Cost Solution

One proven strategy to achieve low-cost relay manufacturing investment in India is to leverage China’s well-established supply chain. China is home to numerous specialized relay socket OEM factories, like CDGKZ, which have decades of experience, ready-made designs, and large-scale production capabilities. By forming a partnership, Indian companies can import semi-knocked down kits or key components from China and assemble them locally. This China to India relay supply chain model drastically cuts costs in several ways:

Economies of Scale: Chinese manufacturers produce relay parts in high volumes, lowering the per-unit cost. Indian partners can purchase critical components (e.g. coils, armatures, contacts, plastic bases) at a fraction of the cost of making them in-house initially. With CDGKZ as a relay raw materials supplier (China), materials that are expensive or unavailable locally can be sourced affordably.

Reduced Capital Expenditure: Instead of investing in expensive injection molds and custom tooling, Indian firms can obtain finished or semi-finished parts from CDGKZ’s relay socket factory. This means a new relay base factory in India can start with a smaller assembly setup rather than a full-fledged manufacturing line for every part. The partnership thus enables a cost-effective relay base factory launch with minimal machinery investment.

Faster Time-to-Market: Setting up a supply chain from scratch is time-consuming. By tapping into an existing China-India relay supply chain, Indian companies save years in development. They can begin assembling relays in months, not years, since design validation and prototyping are already done by the OEM. This agility is crucial in capturing market opportunities quickly.

Import Duty Advantages: Often, importing components incurs lower tariffs than importing finished goods. Local assembly qualifies the end product as “Made in India,” which may enjoy tax benefits or easier access to government procurement. By producing relay sockets in India via Chinese parts, companies achieve import substitution and align with national self-reliance goals

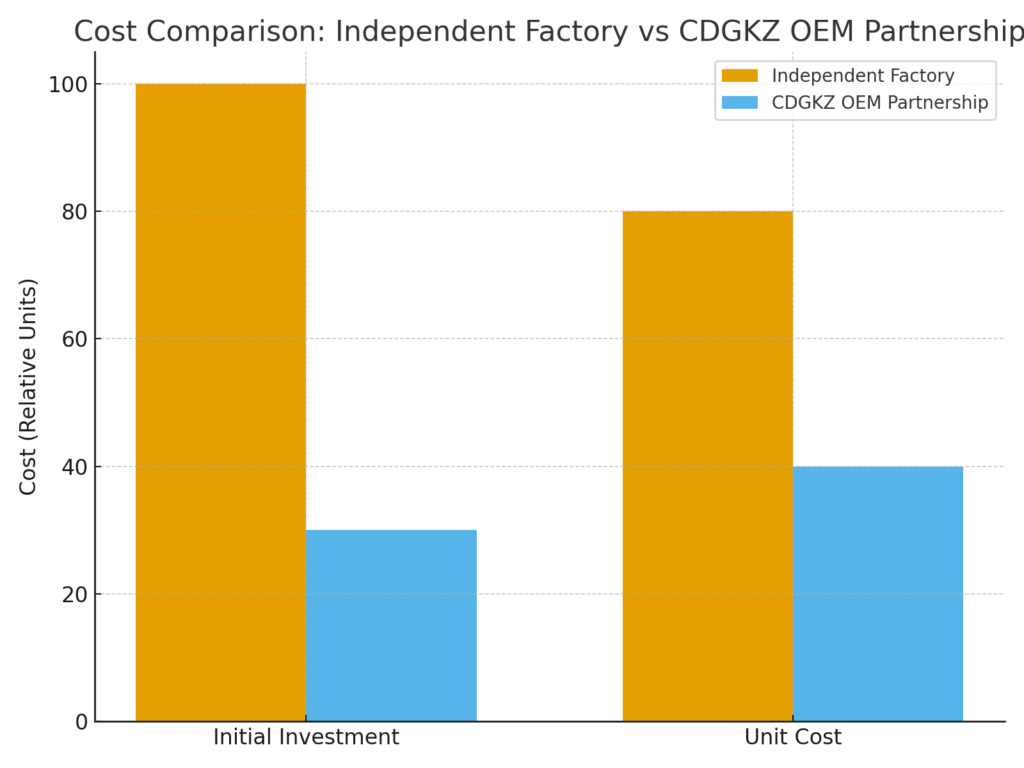

| Category | Independent Factory | CDGKZ OEM Partnership |

|---|---|---|

| Initial Investment | 100 (High) | 30 (Significantly Lower) |

| Unit Cost | 80 (High) | 40 (Reduced) |

| Values are relative units for comparison. Independent factories face high startup and production costs, while partnering with CDGKZ significantly reduces both. | ||

Beyond cost savings, a partnership model brings technical guidance. Chinese OEMs like CDGKZ have seasoned engineers who can assist in setting up the assembly process in India, training local staff, and troubleshooting production issues. This transfer of expertise ensures that the Indian assembly line can achieve the same quality outputs as the Chinese factory from day one. In essence, the Indian company gets a “factory-in-a-box” – the blueprint, components, and mentoring – drastically lowering the barrier to entry. Such collaboration exemplifies relay manufacturing localization in India with global support.

Real-world examples back this approach. For instance, an Indian firm partnering with a Chinese manufacturer to produce advanced automotive relays domestically projected ₹40 crore investment and expected to generate ₹250 crore in business by 2030. By producing components domestically, they aim to “drive import substitution” and give local OEMs access to advanced technology at home. This case mirrors how working with a Chinese partner can make a high-tech manufacturing venture viable in India, aligning with both Make in India and cost-efficiency.

Key Takeaways:

Chinese Supply Advantage: Tapping into China’s relay component supply chain cuts material costs and provides immediate access to high-quality parts.

Lower Investment: An OEM partnership drastically reduces the capital needed for tooling and R&D, enabling affordable relay socket production in India that would otherwise be cost-prohibitive.

Quick Scaling: Importing ready components for local assembly speeds up launch and helps Indian manufacturers meet market demand faster, all while achieving import substitutionbusiness-standard.com.

Learn more: How OEM Partnerships Reduce Manufacturing Costs (detailed cost breakdown and supply chain benefits)

CDGKZ OEM/ODM Partnership – Building Your Relay Socket Factory

CDGKZ (Zhejiang Chuangdao Electric) is a prime example of a partner that offers turnkey solutions for Indian companies aiming to produce relays and sockets locally. As a dedicated relay socket OEM manufacturer (China to India), CDGKZ has more than 30 series of relays and sockets, with hundreds of proven models. Collaborating with CDGKZ is essentially engaging a one-stop India relay socket manufacturing partner – one that provides both the hardware and the know-how needed to establish your own production line in India.

Here’s what a partnership with CDGKZ entails:

Comprehensive OEM/ODM Support: CDGKZ can manufacture relay and socket components under your branding (OEM) and even customize designs to your specifications (ODM). Their Chinese relay socket factory handles the precision manufacturing of parts like contacts, coils, bases, and metal pins. These semi-finished parts or kits are then shipped to India for final assembly. Your local operation focuses on assembling and testing, while CDGKZ ensures you have a steady supply of quality components.

Technology Transfer & Training: Crucially, CDGKZ doesn’t just sell parts – it shares expertise. Through a structured relay socket technology transfer to India, CDGKZ’s engineers guide your team on assembly processes, quality control, and best practices. This mentorship accelerates your learning curve. In effect, the relay technology partnership (China–India) means you’re not starting from zero; you inherit years of CDGKZ’s manufacturing experience. Indian engineers and technicians can get hands-on training, ensuring the Made in India relays match the performance of those made in China.

Molds and Equipment: Setting up a relay base factory often requires expensive molds and fixtures. CDGKZ can provide these as part of the partnership. For example, if plastic relay socket bases need to be molded locally to meet local content rules, CDGKZ can supply the mold tools or even help set up localized production for certain parts. This hybrid approach keeps investment low while gradually increasing localization.

Customized Solutions for India: CDGKZ is familiar with the Indian market’s requirements, whether it’s preferences in design (e.g., socket styles compatible with existing systems) or documentation needed for compliance. As a result, they offer CDGKZ relay solutions for India that are tailored to local needs. Everything from product packaging to after-sales support can be coordinated in the partnership, giving Indian companies a full solution package to become a relay manufacturer.

| Aspect | Independent Factory | With CDGKZ Partnership |

|---|---|---|

| Initial Investment | Very high (molds, machines, full production line) | Lower (CDGKZ supplies parts, molds, equipment support) |

| Production Model | Full in-house manufacturing of all components | Hybrid model: components made in China, assembly in India |

| Technology & Training | Build knowledge from scratch, long learning curve | CDGKZ provides technology transfer, engineer guidance & training |

| Quality Assurance | Risk of inconsistent quality during ramp-up | Established QA processes from CDGKZ ensure consistent standards |

| Customization | Limited; requires in-house R&D investment | OEM/ODM support: coil, contacts, housing, branding, packaging |

| Market Adaptation | Slower adaptation; requires local trial & error | Tailored to Indian requirements (design, compliance, documentation) |

| Time-to-Market | Years to set up and validate production | Months to launch, leveraging CDGKZ’s validated designs |

| Summary: Independent factories require heavy investment and long timelines. Partnering with CDGKZ reduces cost, accelerates setup, transfers technology, and ensures quality. | ||

By choosing CDGKZ as an OEM relay socket manufacturer partner, Indian businesses essentially get a plug-and-play factory blueprint. This dramatically lowers the entry barrier. A venture that might have been financially unfeasible becomes realistic because the heavy lifting (design, development, precision manufacturing) is handled by an expert with an existing infrastructure. All the while, the Indian company retains its brand and fulfills the “Made in India” mandate by doing assembly and final production locally. It’s a win-win: CDGKZ expands its market reach, and the Indian firm transforms into a manufacturer with minimal pain.

Key Takeaways:

Turnkey Factory Setup: CDGKZ provides end-to-end assistance – from components to technical training – essentially incubating India’s relay producers.

Minimized Risk: With a proven partner, Indian companies avoid trial-and-error costs. The designs are field-tested, and supply is assured, making the venture far less risky.

Fast-Track Growth: This partnership model enables scaling production quickly. As demand grows, Indian assembly operations can expand with continued OEM support, evolving into full-fledged manufacturing over time.

Learn more: CDGKZ Relay Socket Solutions & OEM Services (explore CDGKZ’s product range and partnership offerings)

Ensuring World-Class Quality (CE, UL, RoHS Compliance)

A common concern when localizing production is whether the locally made product will match global quality standards. With CDGKZ’s partnership, the answer is a resounding yes. CDGKZ’s relays and sockets are engineered to meet international certifications like CE, UL, and RoHS, and these standards carry over to the units assembled in India. Maintaining high quality is non-negotiable, especially since relays are critical components in industrial automation and electrical safety systems. Here’s how quality compliance is achieved:

CE Marking (European Standards): The CE mark on a relay or socket means it conforms to the health, safety, and environmental protection requirements of EU regulations. When you partner with CDGKZ, you are using designs and components that have been assessed for CE compliance. By following the prescribed assembly and testing procedures, Indian-made relays can legitimately bear the CE mark, enabling exports to Europe and assuring domestic customers of product safety. (Note: CDGKZ provides the technical documentation and test reports needed for your certification process.)

UL Certification (North American Standards): Underwriters Laboratories (UL) certification is crucial for electrical products entering the US or Canadian markets. CDGKZ’s factories are experienced in meeting UL standards – from material flammability ratings to creepage distances on circuit boards. UL’s recognized expertise provides critical credibility to authorities and the marketplace. By using UL-certified components from CDGKZ and adhering to their manufacturing guidance, your Indian-produced relays can be UL listed or recognized, signifying they meet rigorous safety benchmarks. This opens doors to global markets and instills confidence in end-users.

RoHS Compliance (Environmental Safety): RoHS (Restriction of Hazardous Substances) is an EU directive that bans specific toxic substances (like lead, mercury, cadmium) in electronics. All CDGKZ relay sockets are built RoHS-compliant, meaning the plastics, solders, and components used are free of those hazardous substances. When assembling these products in India, you inherit the same compliance. This is vital not only for meeting regulations in Europe and other regions but also for environmental stewardship. Indian customers are increasingly aware of RoHS, so being able to claim compliance is a market advantage.

Crucially, quality control processes will be part of the tech transfer. CDGKZ helps establish testing procedures in the Indian facility – for instance, contact resistance tests, dielectric strength tests, and lifecycle testing for relays. They may supply testing jigs or even automated test equipment. This ensures that every unit produced meets the spec. In addition, CDGKZ’s own QA team can collaborate in the early stages to double-check the output from the Indian line. The result is consistency: whether a relay socket is made in China or assembled in India, it performs reliably and is certifiable to the same standards.

It’s worth noting that having internationally certified products greatly expands the market reach of your Made in India relays. You can confidently sell to OEMs in India who supply global markets, and even export directly, knowing that certifications like CE and UL are in place. In essence, relay socket CE, UL, RoHS compliance is a built-in feature of partnering with a top-tier OEM like CDGKZ, not an afterthought.

Key Takeaways:

Built-In Compliance: CDGKZ’s designs adhere to CE, UL, and RoHS from the start, so Indian-assembled units can readily meet these global standards.

Quality Systems Transfer: Part of the partnership is implementing robust quality control in the Indian facility – ensuring every relay meets international performance criteria.

Global Market Access: With certified products, Indian manufacturers can cater to both domestic and export markets, turning local manufacturing into a globally competitive venture.

Learn more: International Standards for Relay Sockets (guide to CE, UL, RoHS requirements for electrical components)

FAQ

Q1: What support does CDGKZ provide to set up a relay & socket factory in India?

A: CDGKZ offers end-to-end support for Indian partners. This includes supplying ready-to-assemble relay and relay socket components, providing the necessary production equipment or molds, and transferring the technical know-how to assemble and test the products. Essentially, CDGKZ delivers OEM kits of relay parts along with detailed assembly instructions. They also train your team on manufacturing processes and quality control. In short, you get a turnkey package – from raw materials to manufacturing expertise – to quickly establish your own relay socket production line in India.

Q2: How does partnering with a Chinese OEM like CDGKZ reduce costs for Indian manufacturers?

A: The cost savings come from multiple angles. First, you avoid the heavy R&D and tooling investment since CDGKZ provides proven designs and existing molds. Second, raw materials and components sourced from China are often cheaper due to mass production – you leverage CDGKZ’s economies of scale. Third, local assembly of imported kits typically incurs lower duties than importing finished products, saving on import taxes. Additionally, with CDGKZ handling the complex manufacturing of sub-parts, your Indian operation can be smaller and more cost-efficient, focusing only on assembly and testing. All these factors significantly lower the total cost of ownership and make relay manufacturing in India financially viable.

Q3: Can locally assembled relays in India meet CE, UL, and RoHS standards?

A: Yes, they can – provided you partner with an OEM like CDGKZ whose components and designs are already certified or compliant. CDGKZ’s relays and sockets are built to satisfy CE and UL requirements and use RoHS-compliant materials. When you assemble these in India following the prescribed processes, the final products can inherit those certifications (with proper auditing and paperwork). Many CDGKZ components come with test reports and certification support, so your end product can be certified much faster. In practice, companies working with CDGKZ have been able to label their Indian-made relays with CE and UL marks, since they adhere to the same specifications and quality controls as the China-made equivalents. Always ensure to coordinate certification efforts with CDGKZ’s team, and you’ll be able to guarantee global-standard quality for your Made in India products.

Conclusion:

India’s manufacturing ambitions in the relay sector can become reality by partnering with experienced players like CDGKZ. Instead of shouldering the entire burden of setup and development, Indian companies can ride on CDGKZ’s low-cost relay & socket solutions to fast-track their “Make in India” journey. The result is a state-of-the-art production line at a fraction of the usual cost, producing world-class relays and sockets right on Indian soil. Whether you’re an entrepreneur or an established electrical OEM, collaborating with CDGKZ gives you the dual advantage of affordable production and proven quality. Embrace the CDGKZ Made in India model today – achieve self-reliant manufacturing without compromising on technology or standards.

Ready to get started? Contact CDGKZ to discuss your relay manufacturing project and see how our China-to-India OEM partnership can jumpstart your success. Let’s build the future of India’s relay industry together – at lower cost and higher quality than ever before