Siemens Compatible Relay Sockets: Cost-Effective Replacements

Selecting the right relay socket is critical for electrical panels, control systems and factory automation. Many engineers rely on Siemens compatible relay sockets for their reliability, yet high costs, long lead times and limited customization can frustrate buyers who need flexibility. This guide introduces cost‑effective Siemens relay socket replacements from China and demonstrates how CDGKZ products serve as a high‑quality, seamless substitute for Siemens bases. We will examine international safety standards, compare features and costs, discuss OEM/ODM benefits and explain why CDGKZ is the CDGKZ Siemens relay socket alternative you can trust.

TL;DR

Cost‑effective alternatives exist: Chinese OEMs like CDGKZ produce Siemens compatible relay sockets that match Siemens dimensions, pin layouts and electrical ratings. These cost‑effective Siemens relay alternatives allow seamless replacement without rewiring.

Compliance with global standards: CDGKZ relay sockets comply with IEC 61984, UL 508 and CSA safety standards, carry CE marking and operate under an ISO 9001 quality management system.

OEM/ODM advantages: Outsourcing production to low‑cost regions like China reduces per‑unit costs and allows customization in colour, material and branding. CDGKZ offers flexible MOQs, private labelling and custom features.

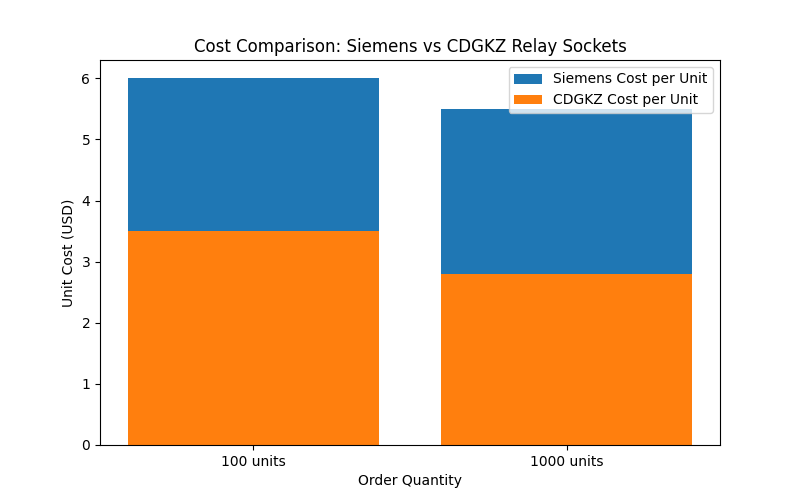

Head‑to‑head comparison: CDGKZ relay bases deliver the same technical performance as Siemens while offering significant cost savings. Our table and chart illustrate price differences for 100 and 1 000 unit orders.

Your trusted partner: With over 15 years of experience in the electrical industry, CDGKZ provides reliable Siemens relay socket replacements, strong supply chain support and customer‑centric service.

Why Seek Siemens‑Compatible Relay Socket Alternatives

Siemens has long been synonymous with high‑quality industrial components. Their relay sockets are robust and widely used in control panels, machinery and automation systems. However, buyers often face three major pain points when sourcing Siemens relay socket replacements:

High cost and rigid pricing: Siemens relays and bases carry a premium price tag. For OEMs, system integrators or distributors, these costs directly affect profit margins. Low‑voltage automation projects with hundreds or thousands of sockets can quickly become expensive.

Long lead times: Global supply chains and strong demand mean that popular Siemens bases often have lead times of six to twelve weeks. Projects with tight timelines cannot afford such delays.

Limited customisation: Standard Siemens sockets are available in fixed colours and terminal styles; custom variations require large minimum orders and lengthy negotiation. When unique branding or special features (such as LED indicators or suppressor circuits) are required, options are limited.

For these reasons, many buyers explore cost‑effective Siemens relay alternatives produced by Chinese OEMs. Companies like CDGKZ manufacture relay bases that are dimensionally and electrically identical to Siemens models. By leveraging efficient production and lower labour costs in China, CDGKZ can offer lower prices without sacrificing quality. The Siemens equivalent relay socket from CDGKZ also accommodates customization requests – from housing colour and logo printing to screw or spring terminals – enabling brand differentiation and application‑specific optimisation. Crucially, these alternatives maintain full compatibility with Siemens relays, meaning existing wiring, DIN rail mounting and panel layouts do not need to change.

Key Takeaways

There are valid alternatives to Siemens relay sockets that provide identical fit and electrical performance at lower cost.

Chinese OEM suppliers like CDGKZ offer rapid production and flexible customisation, reducing lead times and allowing private labels.

Exploring Siemens relay socket replacements can dramatically cut project costs while maintaining quality and compliance.

Internal link suggestion: Learn more about DIN rail relay base compatibility

Ensuring Safety and Compliance: IEC 61984, UL 508, CSA, CE and ISO 9001

Safety is paramount when replacing relay sockets. Siemens products carry multiple certifications, and any alternative must meet the same stringent requirements. The following standards govern the design and testing of relay bases:

IEC 61984 – Global baseline The International Electrotechnical Commission’s standard IEC 61984 specifies safety requirements and tests for connectors (including relay sockets) with rated voltages above 50 V and up to 1 000 V AC/DC. National standards such as UL and CSA are based on this IEC foundation. CDGKZ relay sockets undergo third‑party testing to validate compliance with IEC 61984, ensuring safe operation under electrical stress, temperature cycling and mechanical wear.

UL 508 – North American control equipment UL 508 covers safety for industrial control equipment such as control panels, motor starters and relays. In North America, connectors used in control cabinets must be tested to UL standards; UL 508 is widely used for this purpose. CDGKZ relay sockets are UL‑listed, meaning they pass tests for dielectric strength, flammability and mechanical durability. Using an UL‑certified socket maintains the UL listing of the overall panel.

CSA certification – Canadian compliance The Canadian Standards Association certifies electrical products for safety. CSA testing verifies that devices meet strict safety requirements and undergo rigorous assessment, granting market access and reducing liability. CDGKZ products carrying the CSA mark assure distributors and installers that the sockets meet Canadian electrical codes. CSA and UL are both NRTLs (Nationally Recognized Testing Laboratories) recognised by OSHA, so acceptance by one is often acknowledged by the other.

CE marking – European market access The CE mark demonstrates that a product complies with EU health, safety and environmental protection requirements. CDGKZ relay sockets bear the CE marking, enabling free circulation throughout the European Economic Area. For detailed guidance on the CE process, see the European Commission’s .

ISO 9001 – Quality management OEM manufacturing demands consistent quality. CDGKZ maintains an ISO 9001 quality management system, which governs processes from raw material inspection to final shipment. The VPIC Group notes that ISO 9001 certification ensures quality across installation, production and service. By following ISO 9001, CDGKZ ensures traceability, documentation and continuous improvement.

Key Takeaways

International standards such as IEC 61984, UL 508 and CSA underpin connector safety and are mandatory for Siemens replacements.

CE marking certifies compliance with EU regulations and allows products to be sold freely across Europe.

ISO 9001 quality management ensures that CDGKZ relay sockets are produced under stringent procedures, providing consistent performance.

Internal link suggestion: Understanding UL and CSA differences in relay components

Comparing Siemens and CDGKZ Relay Sockets: Cost, Features and Availability

Cost is a decisive factor when choosing between Siemens and CDGKZ relay sockets. In addition to price, buyers must evaluate technical specifications, availability and customisation. The table below compares a typical Siemens base (e.g., an 8‑pin DIN‑rail socket used with SIRIUS relays) with its CDGKZ equivalent:

| Attribute | Siemens base | CDGKZ equivalent |

|---|---|---|

| Contact rating | 10 A at 250 V AC | 10 A at 250 V AC |

| Socket type | DIN rail, 8‑pin | DIN rail, 8‑pin |

| Standards & compliance | IEC 61984, UL 508, CSA, CE | IEC 61984, UL 508, CSA, CE, ISO 9001 |

| Relative unit cost | $$ (higher cost) | $ (approx. 30–40 % cheaper) |

| Customisation (colour, branding) | Limited | Available through OEM/ODM |

| Minimum order quantity (MOQ) | Typically high | Low or negotiable |

| Lead time | 6–12 weeks | 2–4 weeks (depending on quantity) |

| OEM/ODM service | Not commonly offered | Available – design modifications and private labelling |

Price differentials become more pronounced at higher volumes. Our cost comparison chart illustrates the unit cost for Siemens versus CDGKZ relay sockets at order quantities of 100 and 1 000 units. As shown, CDGKZ remains significantly cheaper across both scenarios thanks to efficient manufacturing in China

Beyond cost, CDGKZ offers custom features that Siemens does not readily provide. These include surge suppression circuits (such as RC snubbers or coil suppression diodes), integrated LED indicators for coil status, spring‑clamp terminals, finger‑safe covers and unique housing colours. OEM and ODM customers can request specific materials (PA66, PBT, FRP) and packaging with their own brand names. Flexible MOQs mean that distributors can order smaller batches to test new markets without committing large capital.

Key Takeaways

CDGKZ relay sockets match Siemens technical specifications while offering significant cost advantages; volume orders can reduce costs by 30–40 %.

OEM/ODM options allow custom colours, terminals, surge suppressors and private labelling, giving distributors product differentiation.

Lower MOQs and shorter lead times help manage inventory and accelerate projects.

Internal link suggestion: Explore relay socket customization options

Selecting a Reliable OEM/ODM Partner for Siemens Relay Socket Alternatives

Choosing a Chinese supplier for industrial relay socket replacement Siemens products requires careful evaluation. Price alone should not drive selection; reliability, engineering capability and after‑sales support are equally vital. When assessing potential partners, consider the following:

Certifications and audits: Ensure the manufacturer holds relevant certifications such as UL, CSA, CE and ISO 9001. Ask for third‑party test reports and audit documentation. CDGKZ provides certificates and test data for all models to validate compliance.

Engineering expertise: A reputable OEM must maintain an experienced engineering team. CDGKZ engineers design and refine moulds, perform finite element analysis to optimise mechanical strength and develop custom sockets that fit Siemens relays precisely. Their in‑house design team can integrate special functions like coil surge suppression, diodes or LED indicators.

Material selection and manufacturing: Quality materials (UL‑recognised PA66, PBT or glass‑filled nylon) ensure high temperature resistance and flammability ratings. CDGKZ has its own injection moulding, machining and assembly workshops, enabling strict control over material quality and dimensional accuracy. Product testing includes 100 % electrical checks, dielectric strength tests and mechanical durability assessments.

Communication and logistics: Time‑zone differences and language barriers can hinder collaboration. CDGKZ employs English‑speaking sales engineers and maintains a global logistics network. They offer prompt responses, technical support and clear communication regarding lead times and shipping.

After‑sales service: A reliable Siemens relay alternative supplier stands behind its products. CDGKZ provides warranties, ongoing technical assistance and readily available samples. They also help customers navigate certification documents during installations or inspections.

Establishing a long‑term partnership fosters mutual trust. Many buyers place small initial orders to evaluate quality and service, then scale up once they’re satisfied. Transparent discussions around specifications, payment terms and delivery schedules ensure smooth cooperation.

Key Takeaways

Evaluate potential suppliers based on certifications, engineering capabilities, material quality, testing processes and service responsiveness.

Strong communication, clear logistics and after‑sales support are essential for successful OEM/ODM collaborations.

Start with sample orders to verify quality before committing to larger purchases.

Internal link suggestion: Guide to qualifying electrical component suppliers

Customisation and OEM Benefits for Siemens Replacement

One of the greatest advantages of sourcing OEM relay bases for Siemens from CDGKZ is the ability to customise the product. Siemens offers a limited range of relay sockets, whereas CDGKZ can tailor designs to specific applications. This flexibility provides competitive differentiation and ensures a perfect fit for unique control panels.

Custom colours and branding: For distributors or panel builders with their own brand identities, CDGKZ can mould housings in customised colours (e.g., black, grey, orange or customer‑specified hues) and imprint logos or part numbers. This enables a private‑label product line without investing in expensive tooling or high MOQs.

Terminal options: CDGKZ provides both screw and spring‑clamp terminals. Spring‑clamp (push‑in) terminals simplify wiring, reduce installation time and improve vibration resistance. For applications requiring finger‑safe terminals, CDGKZ designs sockets with shielded contact points to meet IP20 protection requirements.

Integrated accessories: Relay sockets can include additional features such as coil suppression diodes (for DC relays) or RC snubber networks (for AC relays) to protect circuits from voltage spikes. Built‑in LED indicators display coil status at a glance. Modular clips, retaining brackets and labelling plates can also be incorporated.

Packaged solutions: CDGKZ offers packaging services tailored to individual distributors. Options include customised cartons, blister packs with QR codes linking to datasheets and instruction manuals in multiple languages. This level of support enhances the customer experience and reinforces brand identity.

Working with an OEM/ODM Siemens relay socket supplier like CDGKZ also streamlines communication. Engineers collaborate directly with the manufacturing team to ensure that design modifications meet functional requirements, and rapid prototyping reduces development time. By consolidating design, tooling, production and logistics under one roof, CDGKZ delivers efficient, cost‑effective solutions.

Key Takeaways

Customised colours, terminals and accessories allow buyers to tailor relay sockets to specific applications and branding needs.

Integrated surge suppression, LEDs and clips enhance functionality and usability of the relay sockets.

Consolidating design, tooling and production with CDGKZ reduces lead times and simplifies communication, producing a high‑quality relay socket factory China experience.

Internal link suggestion: Discover our OEM/ODM services for relay sockets

FAQ

Is it safe to replace Siemens relay sockets with CDGKZ products?

Yes. CDGKZ relay sockets are fully Siemens compatible and meet IEC 61984, UL 508, CSA and CE standards They have identical pin configurations and contact ratings, ensuring safe, reliable operation when used with Siemens relays.

Will using Chinese OEM relay sockets void my UL/CSA listing?

No. As long as the replacement socket is UL or CSA certified, using an OEM replacement will not void a control panel’s certification. Both UL and CSA are nationally recognised testing laboratories. CDGKZ relay sockets carry UL and CSA marks; keep the certification documents for inspections.

What advantages do OEM/ODM services provide over buying branded sockets?

OEM/ODM services offer customisation, cost savings and flexible minimum order quantities. Manufacturers like CDGKZ can produce Siemens relay socket equivalent manufacturers to your specifications while maintaining compliance with international standards. Outsourcing to low‑cost regions reduces per‑unit costs and allows for rapid design iterations.

Conclusion and Call to Action

Switching to a Siemens CDGKZ Siemens relay socket alternative can yield substantial benefits. CDGKZ relay sockets offer the same electrical performance and reliability as Siemens bases while meeting international standards such as IEC 61984, UL 508, CSA and CE. By leveraging OEM manufacturing in China and ISO 9001 quality management, CDGKZ delivers cost‑effective Siemens relay socket replacements with flexible customisation and short lead times.

If you are a distributor, panel builder or OEM seeking a reliable Siemens relay replacement supplier, contact CDGKZ today. Our team can provide samples, technical datasheets and competitive quotations. Experience how high‑quality engineering, stringent testing and customer‑focused service make CDGKZ the ideal partner for your next project.