Have you ever wondered how complex electrical control systems stay organized, safe, and easy to maintain? If you’re diving into industrial automation or even a DIY smart home project, chances are you’ve come across the term DIN rail relay socket—but what exactly is it, and why does it matter so much?

Whether you’re a complete beginner or just looking to sharpen your knowledge, this guide will walk you through everything you need to know about DIN rail relay sockets. By the end, you’ll not only understand their crucial role but also be ready to choose and install one like a pro. Ready to power up your understanding? Let’s get started!

What is a Din Rail Relay Socket?

What Is a DIN Rail?

A DIN rail is a metal mounting rail standardized by the German Institute for Standardization (DIN – Deutsches Institut für Normung), commonly used in electrical and control systems to mount modular components such as circuit breakers, relays, and terminal blocks. The most common type is the TS35 rail (also known as the 35mm standard or top-hat rail), which is 35 millimeters wide and widely used in industrial and distribution applications. DIN rails are typically made of galvanized steel or aluminum and are known for their robust structure, ease of installation, and high degree of standardization.

What Is a Relay Socket?

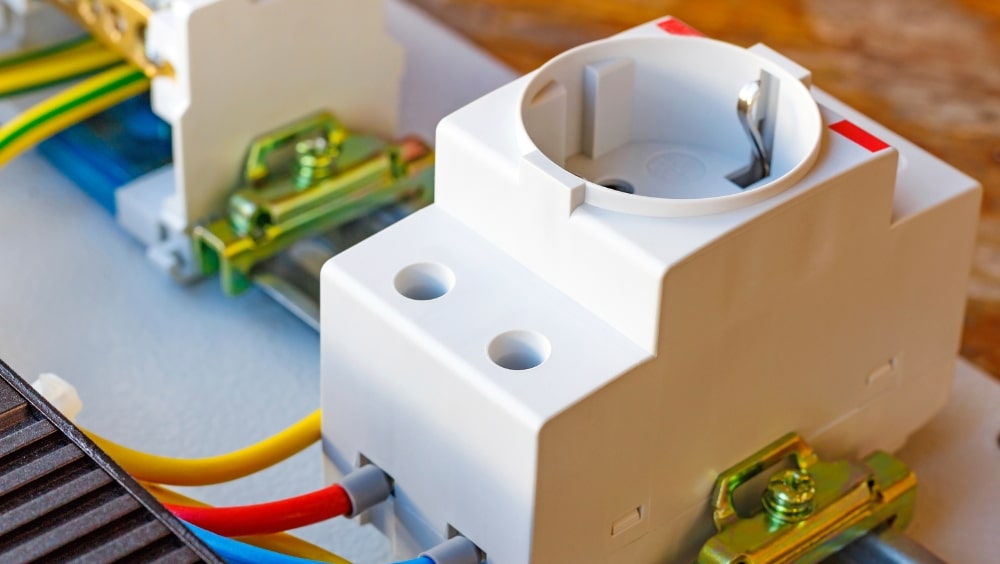

A relay is an electrically operated switch used to control circuits by opening and closing contacts in another circuit. A relay socket is a specially designed base that allows for easy installation, connection, and replacement of relays. It provides a secure interface between the relay and the electrical wiring, ensuring reliable connections, mechanical stability, and added protection for both the relay and the circuit.

DIN rail relay sockets differ from traditional hardwired relay mounting methods in that they are designed to snap directly onto standard DIN rails, enabling quick installation and modular arrangement within control panels. Unlike soldered or screw-mounted relays, DIN rail sockets offer greater flexibility, ease of maintenance, and simplified wiring, which is especially valuable in industrial and automation applications.

How a DIN Rail Relay Socket Works

A DIN rail relay socket is designed to securely hold a relay and facilitate its integration into control systems. The relay is plugged directly into the socket, aligning its pins with the corresponding terminals to ensure proper electrical connections. The socket itself is mounted onto a DIN rail by snapping or sliding it into place, using a spring-loaded or clip-on mechanism for secure attachment. The terminal layout on the socket provides clearly labeled connection points for coil inputs and switching contacts (e.g., NO, NC, COM), enabling straightforward wiring to control circuits while ensuring organized and reliable operation.

Why DIN Rail Relay Sockets are Important

- Standardized Installation and Wide Compatibility

DIN rail relay sockets are manufactured in compliance with internationally recognized standards such as IEC and DIN. This standardization ensures that a wide variety of relay models and brands can be easily mounted and replaced without compatibility issues. It simplifies design considerations and procurement, allowing engineers and technicians to select relays from multiple manufacturers with confidence that they will fit securely and function properly. - Efficient Use of Space in Control Cabinets

The compact, modular design of DIN rail relay sockets enables them to be mounted neatly on a standard 35mm DIN rail, optimizing the use of available space inside control panels. This is particularly important in industrial environments where space is limited and panel layouts must be organized to accommodate many components while maintaining accessibility and airflow. - Simplified Wiring and Clear Terminal Identification

Relay sockets feature clearly marked terminals for coil inputs, normally open (NO), normally closed (NC), and common (COM) contacts. This organized terminal layout minimizes wiring errors during installation and makes troubleshooting faster and more straightforward. Proper labeling also helps ensure compliance with electrical codes and improves safety for maintenance personnel. - Quick and Tool-Free Relay Replacement

One of the most significant advantages of DIN rail relay sockets is the ease with which relays can be inserted or removed without disturbing the wiring or requiring specialized tools. This plug-and-play feature drastically reduces downtime during maintenance or component failure, allowing for rapid replacement and minimizing production losses. - Enhanced Safety and Reliability

Constructed from flame-retardant, heat-resistant, and electrically insulating materials, DIN rail relay sockets help maintain a safe operating environment. The secure mechanical mounting and firm terminal connections prevent issues such as loose wiring, contact failure, and short circuits, which can lead to system faults or hazards. This reliability is critical in industrial applications where equipment failure can have serious consequences. - Facilitates Modular and Scalable Automation Systems

In modern industrial automation, systems often need to be scalable and modular for easy upgrades and expansions. DIN rail relay sockets support this flexibility by allowing relays to be added, removed, or rearranged on the DIN rail with minimal disruption. This modularity supports faster project timelines and future-proofs control panel designs. - Cost-Effectiveness Over the Long Term

Although DIN rail relay sockets may add an initial cost compared to hardwired relay mounting, the savings in installation time, maintenance efficiency, and reduced downtime translate to significant cost benefits over the life of the system. Easier troubleshooting and replacement lower labor costs and improve system uptime, which is vital for industrial productivity.

Summary:

DIN rail relay sockets are essential components in modern electrical and automation systems. They provide a standardized, space-saving, safe, and reliable method for mounting relays while simplifying wiring, maintenance, and system scalability. Their use leads to better organized control panels, reduced downtime, and enhanced overall system performance.

How to Choose the Right DIN Rail Relay Socket

1. Confirm Relay Model Compatibility

Select a socket that matches the relay model you are using. Ensure that the number and arrangement of pins correspond exactly to guarantee proper installation and connection of the relay.

2. Check Current and Voltage Ratings

Verify the socket’s rated current and voltage parameters to ensure it can handle the electrical load during relay operation, preventing safety hazards or equipment damage due to mismatched specifications.

3. Choose the Appropriate Pin Layout

Pay attention to the pin arrangement on the socket to ensure it aligns correctly with the relay’s pins, avoiding poor contact or installation difficulties.

4. Determine the Type of Connection Terminals

Select the terminal type based on the installation environment and ease of maintenance. Screw terminals provide secure and reliable connections, while spring terminals offer quicker wiring and are suitable for frequent maintenance.

5. Consider Additional Features and Quality

If needed, choose sockets with extra features such as indicator lights, test buttons, or dust and vibration protection to enhance system reliability and ease of operation. Also, select sockets made from high-quality materials and reputable brands to ensure durability and safety.

When to Use a DIN Rail Relay Socket

DIN rail relay sockets are commonly used in control panels and industrial automation systems where organized and space-efficient installation is needed.

They allow relays to be quickly mounted on DIN rails, making panel layouts cleaner and easier to manage.

They are ideal when relays require frequent maintenance or replacement.

The socket design allows for tool-free removal and insertion of relays without disturbing the wiring, which saves time and reduces downtime.

Use them when system flexibility and scalability are important.

DIN rail sockets support modular upgrades and reconfiguration, making them perfect for evolving electrical systems.

DIN Rail Relay Socket Applications

| Scenario | Description |

|---|---|

| Industrial Panels | Mounting relays for machinery and automation control. |

| Building Automation | Used in HVAC, lighting, and security systems. |

| Power Distribution | Switching circuits safely in control cabinets. |

| Renewable Energy | Controlling inverters and battery management. |

| Transportation | Relay connections in railways and traffic systems. |

| DIY & Smart Home | Easy relay integration for automation projects. |

Industrial Control Panels

Used extensively in manufacturing and process control panels for mounting relays that manage machinery, motors, and automation sequences.

Building Automation Systems

Employed in HVAC controls, lighting systems, and security systems to enable easy relay installation and maintenance.

Power Distribution Units

Integral in power control and distribution cabinets where relays are needed to switch circuits safely and reliably.

Renewable Energy Systems

Utilized in solar and wind power installations to control inverters, battery management, and protection circuits.

Transportation Systems

Applied in railway signaling, vehicle control systems, and traffic management for robust and maintainable relay connections.

DIY and Smart Home Projects

Favored by hobbyists and professionals for easy integration of relays into home automation setups.

Installation and Safety Tips

When installing a DIN rail relay socket, safety and proper procedures are essential. Here are some practical tips:

- Power Off First: Always disconnect power before installing or replacing the relay socket to avoid electric shock or equipment damage.

- Use the Right Tools: Use insulated screwdrivers, wire strippers, and other proper electrical tools to improve both efficiency and safety.

- Follow Wiring Standards: Connect input and output terminals according to the wiring diagram. Use wire markers to clearly label each wire to prevent mistakes.

- Avoid Overload: Make sure the socket’s rated current and voltage match your application. Overloading can lead to overheating or failure.

- Check for Stability: After installation, ensure the socket is securely locked onto the DIN rail and all terminals are tightened properly.

Frequently Asked Questions (FAQ)

Q1: Are DIN rail relay sockets compatible with all types of relays?

A1: No. You must choose a socket that matches your relay’s pin layout, voltage/current rating, and model. Refer to the manufacturer’s compatibility charts for accuracy.

Q2: Can relay sockets be reused?

A2: Yes, as long as the socket isn’t physically damaged and the contacts are in good condition. Always inspect the terminals for oxidation or looseness before reusing.

Q3: What brands are recommended?

A3: Trusted brands include Omron, Schneider Electric, Phoenix Contact, Finder, and Weidmüller. These brands offer high-quality, reliable, and standard-compliant relay sockets.

Q4: How can I ensure the socket is securely installed?

A4: After mounting, gently shake the socket to check for movement. Also, confirm that the locking tab is fully engaged with the DIN rail.

Q5: Can I use a DIN rail relay socket in home DIY projects?

A5: Absolutely. Many home automation control panels and small electrical enclosures use DIN rail systems. They’re easy to install and maintain, even for DIY enthusiasts.

Conclusion

Though compact in size, DIN rail relay sockets are indispensable components in electrical control systems. For beginners, understanding their structure, function, and installation is a crucial first step toward mastering professional automation wiring.

By using DIN rail relay sockets, you can gain several advantages:

- Improved wiring efficiency

- Modular equipment installation

- Easier maintenance and replacement

- Enhanced system reliability and visual organization

Whether you’re working on an industrial control panel, an automation project, or a DIY smart home setup, a high-quality DIN rail relay socket can make a significant difference.

If you’re looking for reliable, professional-grade components, CDGKZ offers trusted solutions designed to meet modern demands in automation and control systems.