Relay Socket Installation and Maintenance Guide

Introduction: Installing relay sockets improperly or neglecting their upkeep can lead to frequent relay failures, overheating, and even safety hazards. Many technicians face common relay socket issues like loose connections or premature socket wear that cause downtime and maintenance headaches. This guide addresses those pain points by explaining proper relay socket installation, wiring methods, and a proactive relay socket maintenance regimen to ensure your relays operate safely and reliably for their full lifespan.

TL;DR – Key Points:

– Use the correct relay socket type and follow proper wiring standards to prevent overheating or failures.

– Always de-energize circuits and double-check connections during relay socket installation for safety and compliance with standards.

– Implement a regular relay socket maintenance schedule: inspect for wear, tighten loose terminals, and clean contacts to extend socket lifespan.

– Troubleshoot common relay socket issues (loose contacts, corrosion, overheating) early. Replace or repair sockets showing failure signs to prevent downtime.

– Adhere to industry standards (IEC, NEC, UL) and use quality components to ensure long-term relay socket reliability and safety.

Proper Relay Socket Installation and Wiring Methods

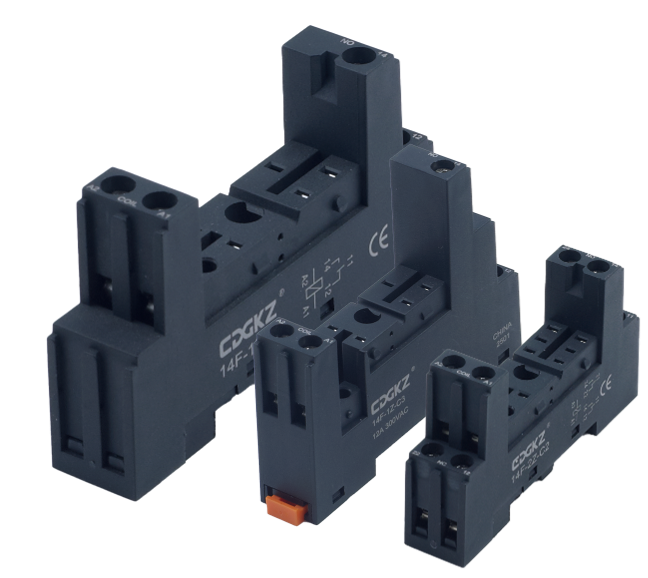

Correct installation and wiring of a relay socket are critical for safe and reliable operation. First, always disconnect power before working to avoid electrical shock or equipment damage. Select a socket that matches your relay’s type and pin configuration – for example, DIN-rail mount, panel mount, or PCB relay sockets (also called relay bases or relay holders) are designed for specific relays. Mismatching a relay with the wrong socket can cause loose fits, overheating, or inefficient operation. Verify the socket’s voltage and current ratings meet or exceed your relay’s requirements and the load it will control.

When wiring the socket, follow wiring best practices to ensure solid connections. Use appropriately gauged wires and strip them correctly; many relay sockets use screw clamp terminals or push-in spring terminals – tighten all screws to the manufacturer’s specified torque so wires don’t loosen under vibration. Each terminal on the socket corresponds to a relay coil or contact pin; refer to the relay’s diagram to connect coil terminals to the control circuit and connect contact terminals to the load circuit in the proper configuration (NO, NC, common, etc.). Maintain clear color-coded wiring if possible to avoid confusion during installation. Securing the socket itself is also important: mount it firmly on a DIN rail or panel so that mechanical stress (e.g. from pulling on wires or vibrations) won’t break the connections.

Adhere to relevant wiring standards and safety codes during installation. In the U.S., for instance, the National Electrical Code (NEC) provides guidelines for safe wiring practices, and similar IEC standards apply internationally. Using UL-listed or CE-marked relay sockets ensures they meet industry safety requirements. For example, IEC 61984 and IEC 61810-1 standards specify safety and insulation requirements for relay connectors and relay-socket combinations. Following these standards helps prevent issues like insufficient creepage distances or insulation failures. Finally, after wiring, perform a voltage and continuity test with a multimeter to verify each connection is correct and secure. This test can catch any wiring mistakes (like a miswired coil or an open contact connection) before powering up, thus avoiding potential short circuits or malfunction.

Key Takeaways:

– Always match the relay socket type to your relay’s specifications to ensure a proper fit and safe operation (e.g. use a DIN-rail socket for a DIN relay).

– Follow proper wiring techniques: use correct wire gauges, tighten terminal screws firmly, and keep wiring organized to prevent loose connections or miswiring.

– Comply with electrical standards (NEC, IEC, UL) during installation for safety – use certified components and verify insulation and grounding meet code.

(Internal Link: Learn more about PCB relay socket selection and specifications.)

Relay Socket Maintenance and Longevity

Once installed, relay sockets require periodic maintenance to ensure longevity and prevent unexpected failures. Implementing a routine relay socket maintenance schedule can catch early signs of trouble before they escalate. A good practice is to visually inspect each socket during scheduled maintenance shutdowns (for example, every 6 or 12 months, depending on usage). Visual inspection should look for any discoloration or burn marks on the socket body, as these indicate overheating. Melted or browned plastic around terminals is a warning sign of excessive heat, while carbon deposits or pitted metal on the contacts suggest arcing or corrosion buildup. Such wear indicators signal that the socket may be nearing end-of-life or in need of service.

Next, ensure all electrical connections remain tight. Vibrations and thermal cycling can loosen terminal screws over time, leading to high resistance and heat. Use a calibrated screwdriver to re-tighten each terminal to the specified torque (often around 0.5–1.0 N·m for many relay sockets) – this avoids both under-tightening (which causes loose, hot connections) and over-tightening (which can strip threads or damage the socket). It’s also wise to perform an electrical test on aging sockets. Measure the contact resistance or voltage drop across the socket’s terminals while the relay is energized. An increasing resistance over successive maintenance checks can indicate that the contacts are corroding or losing tension. Likewise, if the relay is activated and you observe unexpected voltage drops, flickering outputs, or a hotspot (unusually warm terminal), those are red flags of deteriorating contacts or wiring. In critical applications, some facilities even do periodic durability tests such as vibration tests or thermal cycling on their relay/socket assemblies to ensure they can withstand harsh conditions over time. (Many manufacturers design relay sockets to pass standards like IEC 60068-2-6 for vibration resistance.)

Cleaning the relay socket contacts is another important maintenance step. Over years of operation, dust, oxidation, and grime can accumulate on the metal contact surfaces, increasing electrical resistance. To clean, first remove the relay from its socket (and of course, power down the equipment). Inspect the relay’s pins and the socket’s female contacts for any signs of corrosion – green or white crusty deposits (oxidation) or dark tarnish on metal. Use an electronics-grade contact cleaner spray to gently dissolve dirt and oxide layers; this type of cleaner evaporates without residue. Then carefully brush the pins and contacts with a soft nylon brush or even a pencil eraser to polish away remaining oxidation. Avoid using abrasive sandpaper unless absolutely necessary for heavy corrosion, and if you do, use ultra-fine grit and ensure no particles remain. After cleaning, let everything dry and consider applying a thin film of dielectric grease on the relay pins and socket contacts before reinserting the relay. A quality dielectric grease will help seal out moisture and prevent new corrosion, thereby maintaining low contact resistance over the long run. Just apply it sparingly on metal surfaces (and not on any plastic parts or where it could interfere with electrical connection).

Beyond these steps, plan for the long-term servicing of relay sockets. Even a well-made socket won’t last forever, especially under heavy loads or harsh environments. Factors like frequent high-current switching, voltage spikes, high ambient temperature, vibration, and humidity all can shorten a socket’s useful life. To maximize service life, mitigate these stresses where possible: for example, use surge protectors or snubber circuits across coils to reduce electrical stress from voltage spikes, and choose enclosures with appropriate IP ratings or conformal coatings to protect sockets in moisture-prone or dusty environments. In general, a quality relay socket that is properly installed and maintained can last for many years, even decades. Keep records of each socket’s installation date, maintenance, and any issues observed. This history helps predict when a socket might need replacement. Some organizations choose to replace critical relay sockets on a fixed interval (e.g. every 5 years) as cheap insurance against failure. Others replace only when inspections indicate wear. Whichever approach, the goal is to prevent unexpected downtime by proactively renewing any socket that shows signs of deterioration.

Key Takeaways:

– Inspect regularly: Schedule routine visual inspections for burn marks, melted plastic, or corroded contacts – these are warning signs of relay socket deterioration.

– Tighten and test: Keep terminals tight (to spec) and periodically measure contact resistance or voltage drop. A rising resistance or intermittent circuit can indicate a failing socket connection.

– Clean and protect: Remove dust and oxidation from socket contacts using contact cleaner and gentle brushing. Apply dielectric grease to prevent corrosion and maintain low-resistance contacts.

– Plan for longevity: Control environmental factors (surges, moisture, vibration) and use high-quality sockets to extend life. Replace sockets on a planned schedule or at first sign of serious wear to avoid sudden failures.

(Internal Link: Explore our Relay Socket Preventive Maintenance Guide for advanced diagnostics and care tips.)

Troubleshooting Common Relay Socket Issues

Even with good installation and maintenance, you may encounter relay socket problems over time. The most common issues include loose or intermittent connections, corrosion of contacts, overheating, and mechanical fatigue of the socket grips. Knowing how to detect and fix relay socket failures promptly will minimize downtime in your systems.

One frequent problem is loose contacts or wiring. If a relay socket’s terminal screws aren’t tight or if the relay isn’t fully seated, the connection can be intermittent. Symptoms of this include the relay chattering (rapid on-off cycling), devices failing to activate consistently, or visible sparking/arcing at the socket. The fix is straightforward: cut power, then tighten any loose terminal screws and ensure the relay is firmly plugged into the socket. Using a multimeter, check continuity from the wire end to the relay pin socket – there should be very low resistance. Any suspiciously high resistance or fluctuating reading might mean the internal socket contact is damaged or corroded. In that case, relay socket repair may involve replacing the socket if the contact can’t grip the relay pin firmly anymore. Attempting to bend or jury-rig a worn contact is not recommended; it’s safer to install a new socket in that scenario.

Overheating is another issue to watch for. Overheating often shows up as a burnt smell, browned plastic, or even melted portions on the socket or wiring insulation. This can be caused by overloaded contacts (for example, switching a current above what the socket or relay is rated for) or by a loose connection creating resistance and heat. If a relay socket is overheating, first verify that the load does not exceed the relay/socket’s amp rating – if it does, you need a higher-rated relay and socket. If the load is within limits, then suspect a poor connection: the socket’s contact or the wiring may be the culprit. Turn off power and inspect the affected contact; if it’s visibly charred or loses spring tension, replace the socket. Also check the wire’s end – a heat-damaged wire should be cut back and re-terminated to ensure a good new connection. Overheating is a serious issue as it can lead to relay socket failure or even electrical fires, so never ignore these signs.

Corrosion and dirt can cause relay contact failure as well. In humid or corrosive environments, the socket’s metal parts might oxidize, leading to increasing contact resistance and eventual failure to conduct. If a relay isn’t energizing the circuit despite the coil clicking, corrosion on the socket contacts could be insulating the connection. The short-term solution is to clean the contacts as described in the maintenance section (using contact cleaner and brushing). In the longer term, consider using sockets with corrosion-resistant plating (e.g. gold-plated contacts for low-current signals, or silver alloy for high-power contacts) and adding environmental protection (sealed enclosures or conformal coating).

Another common issue is relay coil not energizing via the socket. If the relay doesn’t pick up when it should, use a multimeter to check that the coil terminals in the socket are getting the proper control voltage. A wiring mistake or broken wire can cause a loss of coil power. Ensure the control switch or PLC output is supplying the voltage to the correct socket pin. If voltage is present at the socket but the relay still doesn’t energize, the relay coil itself could be bad – try swapping in a new relay. If the new relay works, the original relay was faulty (not the socket). However, if the problem persists with a new relay, this points back to the socket – possibly a bent or loose coil contact inside the socket not making good contact with the relay’s pin. Again, replacing the socket is the reliable cure for an internal contact issue.

For mechanical issues, some plug-in relays use retaining clips or brackets to hold them in the socket (especially for high-vibration situations). If your relay is popping out or not staying seated, check that any retaining clip is correctly installed and not bent or broken. In high-vibration machinery, use relay sockets that have spring clamp terminals and secure relay hold-down clips designed for that environment. If vibrations are causing recurrent issues, you might need to relocate the relay to a less severe location or use solid-state relays (which have no moving parts and often integrate differently).

After any troubleshooting fix, always test the system thoroughly. Activate the relay a few times under load and monitor if the issue recurs. If a particular socket has needed repeated fixes (like multiple cleanings for corrosion or frequent tightening), that’s a good candidate for preemptive replacement. Failure prevention is better than constant repairs – if a socket shows chronic problems, install a new high-quality replacement rather than risking an unexpected failure at a critical moment.

Key Takeaways:

– Loose connections and overloaded contacts are top causes of relay socket problems – they lead to intermittent operation and overheating. Keep connections tight and stay within ratings to avoid these issues.

– Overheating signs (burnt smell, melted plastic) require immediate action: disconnect power, find the cause (loose terminal or overload), and replace any damaged sockets or wires to prevent fire risk.

– Corrosion or wear can cause relay contact failure. Clean corroded contacts and consider environmental protections, but replace the socket if contacts lose their spring tension or are severely pitted.

– When in doubt, replace a suspect relay socket rather than attempting makeshift repairs – a fresh socket is often the safest solution to restore reliability.

(Internal Link: See our Relay Troubleshooting Checklist for detailed diagnostics and solutions.)

Standards and Best Practices for Relay Socket Safety

Safety and reliability go hand-in-hand when dealing with relay sockets. Ensuring compliance with wiring standards and best practices is one of the most effective ways to prevent relay socket failures. Always use relay sockets and wiring materials that meet relevant industry standards or certifications. For example, choose sockets that are UL Recognized or CSA certified for use in your region, as this indicates they have passed safety testing for flammability, dielectric strength, and other criteria. Internationally, IEC standards such as IEC 61984 (for connector safety) and IEC 61810-1 (for relay safety) govern the design of relay sockets and their insulation properties. Using components that adhere to these standards provides a baseline of quality and safety. Additionally, follow any manufacturer-specific guidelines for the relay and socket – manufacturers often specify compatible combinations of relays and sockets and may warn that mixing brands or using non-approved sockets could reduce the rated voltage or current capacity due to differences in design.

Electrical codes are another critical aspect. Adhering to your local electrical code (such as NFPA 70: the National Electrical Code in the US, or IEC 60364 in Europe) during installation not only ensures safety but also is legally required in most jurisdictions. These codes cover things like proper grounding of relay socket assemblies, enclosure requirements if the socket is in a control panel, and the separation of control (low-voltage) and power (high-voltage) wiring. Compliance prevents hazards like electric shock, short-circuits, and fires. Regular inspections or audits (sometimes mandated by regulation for industrial installations) should verify that your relay wiring and socket installations remain in code compliance over time. Non-compliance can lead to accidents as well as legal penalties.

To further protect relay sockets and ensure long life, implement preventative measures. If the application is prone to voltage spikes (for instance, driving large inductive loads), use appropriate surge suppression across the relay contacts or coil – e.g. RC snubber circuits or MOVs – to shield the socket and relay from electrical stress. In environments with a lot of dust, water, or corrosive gas, select sockets or enclosures with a high IP rating (ingress protection). An IP65 or IP67 enclosure can keep dust and moisture out, which is vital for maintaining the integrity of the socket connections. Likewise, if temperature extremes are expected, choose materials rated for those conditions or provide heating/cooling as needed to keep the relay and socket within a safe operating range. For high-vibration conditions, look for sockets specifically advertised as “vibration-resistant” and follow mounting recommendations (sometimes adding a cushioning pad or using screw-down sockets instead of clip-in ones can help).

Relay socket failure prevention ultimately comes down to a combination of good component selection, proper installation, and proactive maintenance. By using the right socket for the job, installing it to code, not exceeding its electrical ratings, and keeping it clean and tight, you eliminate the most common failure modes. Additionally, keep spares of critical relay sockets on hand – if one shows signs of impending failure, you can quickly swap in a new one during scheduled downtime rather than run it to failure. This kind of forward-thinking approach saves costly unplanned outages and ensures your electrical control systems remain safe and dependable.

Key Takeaways:

– Use certified relay sockets that meet international standards (IEC, UL, etc.) to ensure baseline safety and performance specifications. Quality components are less likely to fail prematurely.

– Follow all relevant electrical codes and standards during installation – proper grounding, insulation distances, and wiring practices per NEC/IEC rules prevent hazards and liability.

– Implement protective measures: surge suppressors for voltage spikes, high IP-rated enclosures for dust/moisture, and vibration-resistant fittings for harsh environments. These precautions significantly reduce the risk of relay socket failure in adverse conditions.

– Preventive approach: Don’t push components beyond their limits and don’t skimp on maintenance. It’s easier to prevent failures by doing things right (and up to standard) than to deal with the aftermath of a neglected, non-compliant installation.

(Internal Link: Learn more about Electrical Standards Compliance for industrial relay installations.)

FAQ

Q1: What are the different types of relay sockets and how do I choose the right one?

A: Relay sockets come in various types, primarily distinguished by their mounting method and pin configuration. Common types include DIN rail mount sockets, which clip onto standard rails in control panels; panel-mount sockets, which often have flanges or brackets to screw them into equipment panels; and PCB mount relay sockets, which allow a relay to plug into a printed circuit board. Additionally, there are sockets for specific relay footprints (e.g. 8-pin octal, 11-pin circular, blade terminals, etc.). To choose the right one, match the socket to your relay’s pin layout and electrical specs. Check the relay’s datasheet or model number – it will usually recommend a compatible socket. Also consider the application environment: for high vibration, choose a socket with a secure locking mechanism or retainer clip; for easy maintenance, use DIN-rail sockets that can be quickly swapped. Ultimately, use the socket type that is designed for your relay model and mounting needs to ensure a reliable connection.

Q2: How often should I perform maintenance or replace a relay socket?

A: The frequency of relay socket maintenance depends on how critical the application is and the operating conditions. As a general rule, it’s good to inspect relay sockets at least once a year under normal conditions. Look for any signs of wear, looseness, or overheating during these inspections. In harsher environments (high humidity, continuous operation, vibration, etc.), consider checking them more frequently – for example every 3-6 months. Cleaning of contacts and re-tightening terminals can be done during these intervals if needed. There isn’t a hard-and-fast replacement interval for all sockets, since a well-made socket in a clean environment can last many years. However, if you notice any relay socket failure signs (burnt contacts, cracked housing, intermittent connectivity) during inspections, you should replace the socket immediately. Some companies adopt a preventive replacement schedule (such as every 5 or 10 years) for sockets that are mission-critical, even if no problems are visible – this is a judgement call based on experience and how much risk you can tolerate. The key is regular inspection: with that, you’ll know when a socket is deteriorating and can plan a replacement before it fails unexpectedly.

Q3: How can I detect if a relay socket is failing?

A: There are a few telltale signs of a failing relay socket to watch for. One is intermittent operation of the relay or the device it controls – for example, if the relay sometimes doesn’t energize or the output load flickers on and off, the socket’s connections might be loose or corroded. Another sign is any visible or olfactory evidence of overheating: a failing socket may have burn marks, melted plastic, or a charred smell around it, usually caused by a high-resistance contact or overload. Heat discoloration near a terminal is a strong indication that the connection is failing. Also, check the relay itself: if you find the relay pins are unusually tarnished or have corrosion after removal, the socket contacts might be corroding (transferring material onto the pins). You can test a suspect socket with a multimeter – measure continuity through each circuit path while gently wiggling the relay; if the continuity breaks or fluctuates, the internal contacts may be worn out. Increasing contact resistance over time (measured during maintenance) is another warning sign. In critical systems, some operators perform thermal scans (using an IR thermometer or camera) on running panels: a hotspot at a relay socket could mean it’s failing. Ultimately, if a relay socket shows any of these symptoms, it’s best to replace it. A failing socket will only get worse, and proactive replacement is cheap insurance against a sudden breakdown.

Conclusion: Proper relay socket installation and maintenance are essential for the longevity and safety of your electrical systems. By following the guidelines in this article – from careful wiring and adherence to standards, to regular inspections, cleaning, and timely troubleshooting – you can significantly extend your relay socket lifespan and avoid costly downtime. Remember that investing a bit of time in preventive maintenance is far easier and cheaper than dealing with emergency failures. If you’re looking to upgrade your relay sockets or need expert assistance, we offer a full range of high-quality relay sockets and support services to help you get the most from your equipment. Contact our team today for help selecting the right relay socket for your needs or for any questions about installation and maintenance – let us help you ensure your operations stay safe and reliable.