Relay Socket Applications in Industrial Automation, Automotive & More

Introduction: In modern electrical engineering, relay socket applications span industries from industrial automation and power systems to automotive electronics and home automation. Many engineers struggle to select the right relay socket to ensure reliable performance and easy maintenance. This article explores how relay sockets – also known as relay bases or relay connectors – are used in these diverse systems and why they are indispensable for safe, efficient control.

TL;DR

- What is a Relay Socket? A relay socket (or relay base) is a mounting interface that securely holds a relay and connects it to a circuit. It provides a stable, reliable connection for the relay’s terminals in industrial, automotive, and other systems.

- Why Use Relay Sockets? Using a socket instead of wiring a relay directly allows quick plug-in replacements or upgrades, greatly reducing downtime. Relay sockets simplify maintenance, enhance safety by insulating live contacts, and protect relays from wear and vibration.

- Where Are They Used? Relay sockets are found in industrial automation, control systems, power systems, robotics, automotive vehicles, home automation, security, telecom networks, HVAC, and more. They enable safe, efficient switching of circuits in everything from factory machines to smart homes.

- Key Benefits: Relay sockets make it easy to swap out faulty relays without rewiring, minimizing system downtime. They ensure reliable connections under harsh conditions (e.g. vibration, heat in engines or machinery) by securing the relay firmly. Many sockets meet UL/CE standards for safety compliance, making them vital in critical applications like energy management and control panels.

Relay Sockets in Industrial Automation and Control Systems

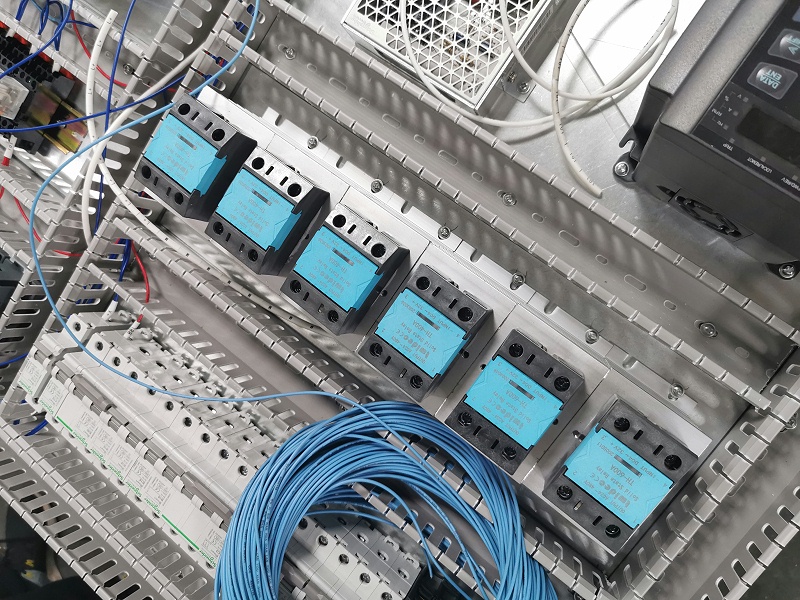

In industrial automation, using a relay socket in industrial automation equipment is crucial for easily managing and replacing the many relays that control machinery. Control systems such as PLC-based production lines and robotics rely on relay sockets to interface low-voltage controls with high-power devices. The relay socket in control panels serves as a mount for each relay, facilitating quick replacement and wiring in factory equipment. For example, a manufacturing line’s control cabinet may contain rows of relay sockets on DIN rails, each holding a relay that drives motors, valves, or safety interlocks. In these environments, relay sockets enable safe and efficient relay control in automated systems. This is especially useful in setups where relays are frequently replaced – a relay socket in control systems allows technicians to swap relays in seconds, minimizing production downtime.

Industrial robotics is another area that benefits from relay sockets. In industrial robotics, relays often start or stop actuators and motors as part of automated tasks. A relay socket in robotics equipment provides a secure connection for these relays amidst vibration and continuous operation. Even heavy machinery like presses or CNC machines use relay sockets in their control circuits to handle high currents safely. Overall, relay socket applications in industrial automation are crucial for process control and automation systems, helping manage operations smoothly and efficiently. By providing a modular interface, relay sockets let engineers maintain and reconfigure complex control panels with less effort and risk.

Key Takeaways:

– In industrial automation and machinery, relay sockets allow quick relay swaps in control panels, reducing downtime.

– They provide secure, standardized connections between control systems (PLCs, etc.) and high-power devices, even under harsh conditions.

– Widely used in factory equipment and robotics for safe, efficient control.

Learn more about PCB relay sockets and their specifications.

Relay Sockets in Power and Energy Systems

Electrical power infrastructure relies heavily on relay sockets for controlling circuits. Installing a relay socket in power systems equipment (e.g. switchgears or substations) allows safe isolation and switching of high-voltage circuits. In power distribution and energy management applications – such as smart grids or building energy control – relay sockets help automate the switching of loads to balance supply and demand. For instance, energy management controllers might use relay sockets to switch between grid power and generators or to shed non-critical loads during peak times. Standards like IEC 61810-1 define safety requirements for low-voltage relays, underscoring the importance of using certified relay sockets in these systems. Engineers often choose sockets that carry UL or CE markings to ensure compliance with electrical safety standards.

Renewable energy installations also incorporate relay sockets. A relay socket in renewable energy systems – such as solar farms and wind turbines – controls connections between generation units, batteries, and the grid. For example, relays in a solar power plant may disconnect panels during maintenance or faults, and these relays plug into sockets for easy service. Likewise, modern battery banks and energy storage units use relay sockets to manage charging and discharging circuits. Using a relay socket in energy storage systems (like large UPS or EV charging stations) provides a reliable way to handle high-current connections and emergency cut-offs. Even in data centers, which are part of critical energy infrastructure, relay sockets appear in power distribution units and backup generator control panels. By ensuring relays can be replaced without shutting down entire systems, relay sockets maximize uptime in these power-critical environments.

Key Takeaways:

– Power distribution and energy systems use relay sockets in switchgear and control panels for safe circuit switching and isolation.

– Renewable energy and storage systems rely on relay sockets to connect/disconnect solar arrays, wind turbines, and battery banks as needed.

– Certified relay sockets (meeting UL, IEC standards) are essential in high-voltage applications to ensure safety and reliability.

Explore our power relay solutions for energy systems.

Relay Sockets in Automotive and Electric Vehicles

In automotive systems, relay sockets are ubiquitous. The relay socket in automotive systems connects critical relays that control everything from headlights and fuel pumps to ignition circuits and radiator fans. Automotive electrical design favors plug-in automotive relay sockets (sometimes called car relay sockets), which let mechanics quickly replace relays without cutting or re-soldering wires. These sockets are designed to withstand the harsh conditions of vehicles – they often feature secure latch mechanisms and rugged housings. In fact, automotive relay sockets are typically compact and sealed to resist dust, moisture, and constant vibration in the engine bay. This robustness ensures a stable connection even as the vehicle jostles on the road.

Modern transportation also includes electric vehicles (EVs), which present high-voltage environments. A relay socket in electric vehicles is used for relays that manage the EV’s power systems – for example, the main battery contactor (a high-power relay) that connects or disconnects the battery pack. These relay sockets must handle higher voltages and currents, enabling safe control over battery charging, motor drive circuits, and safety disconnects. In EV charging stations or onboard chargers, relay sockets likewise allow quick replacement of relays that endure frequent switching. Broader automotive systems like trucks, buses, and even railway signaling equipment also employ relay sockets for reliable switching. From controlling engine management and security systems to operating electric drivetrain components, relay sockets ensure that automotive relays can be serviced easily, keeping vehicles and transit systems running with minimal downtime.

Key Takeaways:

– Automotive relay sockets (car relay sockets) are used in vehicles to plug in relays for lights, ignition, engine control, etc., and are built to withstand vibration and heat.

– In electric vehicles, relay sockets hold high-voltage relays (for batteries and chargers), providing safe, modular connections for power control.

– Rugged, often sealed designs of automotive relay sockets protect against moisture and dust, ensuring reliability in harsh environments.

Learn more about automotive relay sockets and connectors.

Relay Sockets in Home Automation and Security Systems

Smart homes and building automation systems also make extensive use of relay sockets. In home automation, a central controller (like a smart home hub or PLC) uses relays to turn appliances and lights on or off. A relay socket in home automation setups allows these control relays to be mounted in an electrical panel or smart relay module, enabling the automation system to easily manage lighting circuits, motorized blinds, garage door openers, and more. Security systems similarly depend on relays: for example, an alarm panel might trigger a siren or door lock via a relay. Using a relay socket in security systems ensures those alarm relays can be quickly replaced during maintenance or upgrades to the security setup. This is important for reliability – a failed alarm relay can be swapped out in seconds to keep the security system fully functional.

In building management, HVAC equipment is another key application. Thermostats and climate controllers often switch heavy loads (furnace blowers, AC compressors) through relays. A relay socket in HVAC systems holds the HVAC control relay that cycles a compressor or fan on and off, isolating the high voltage from the control electronics. By using a socket, HVAC technicians can replace a burned-out relay without disturbing the wiring or replacing the whole control board. Beyond traditional home uses, relay sockets also appear in smart IoT devices and home energy management systems – for instance, controlling water pumps, electric water heaters, or backup generators in a residential setting. The home automation and security realm values relay sockets for their safety and convenience: they keep live mains wiring enclosed, reduce the risk of wiring errors, and speed up any repairs. In essence, relay sockets are integral in systems designed for controlling lighting, heating, and security in smart homes, as they make the hardware layer of automation more modular and reliable.

Key Takeaways:

– Home automation controllers use relay sockets to control household circuits (lights, appliances, etc.), allowing easy relay replacement and isolation from high voltage.

– Security systems (alarms, access controls) employ relay sockets to integrate sirens, door locks, and sensors, improving maintenance and uptime of safety devices.

– In HVAC and building controls, relay sockets switch heavy loads like fans and compressors, and let technicians service relays without rewiring.

Discover more building automation control components and solutions.

Relay Sockets in Telecom and Data Center Systems

Telecommunication networks and IT infrastructure also benefit from relay socket technology. In telecom facilities, a relay socket in telecom systems equipment can be found in switching systems and network control units. For example, telephone exchange racks and cellular base stations may use relays (and sockets) for routing signals or managing backup power. According to industry use cases, relay sockets are commonly found in signal routing and control systems for network infrastructure. They help telecom engineers replace relays in critical circuits (like those that switch backup links or control transmission lines) without service interruption. Relay sockets in these systems ensure that even if a relay fails, it can be swiftly swapped to restore full connectivity.

Data centers, which house servers and networking gear, utilize relay sockets mostly in their facility management and power distribution units (PDUs). A relay socket in data centers might hold relays that control large power circuits—for instance, toggling between primary power, generators, and UPS (Uninterruptible Power Supply) backups. They may also appear in environmental control systems (like triggering emergency cooling or fire suppression) that require reliable switching. Using relay sockets in these contexts speeds up maintenance of critical infrastructure; technicians can pull and replace a faulty relay module in a power panel without lengthy downtime. Additionally, many monitoring systems in IT and telecom environments use relay outputs to trigger alarms or redundancy measures. The use of a relay socket in monitoring systems (such as network monitoring devices or environmental sensors) allows those systems to automatically activate alarms, backup fans, or shutdown procedures when thresholds are breached. This modular approach is invaluable in high-reliability environments: it keeps systems running smoothly by making every relay easy to inspect, test, and replace.

Key Takeaways:

– Telecom systems use relay sockets in network infrastructure for signal switching and to manage power to critical communication equipment.

– Data centers employ relay sockets in power distribution and environmental control systems, enabling quick maintenance of power relays and safety devices.

– Monitoring and alarm systems leverage relay sockets to trigger alerts or backup operations when faults are detected, ensuring rapid response and minimal downtime.

Learn more about relay solutions for telecom and data center applications.

FAQ

Q1: Why is a relay socket important, and how does it differ from wiring a relay directly?

A1: A relay socket is important because it provides a safe, modular way to mount and connect a relay without permanent soldering. In electrical engineering practice, plugging a relay into a socket allows quick replacement if the relay fails, whereas a directly wired (soldered) relay is harder to swap. The socket securely holds the relay and connects it to the circuit via screw or spring-clamp terminals. This means maintenance is as simple as pulling out the old relay and plugging in a new one – no need to rewire the whole circuit. Additionally, the socket’s insulating housing protects technicians from live contacts and reduces wear on relay pins. In short, using a relay socket improves safety, speeds up repairs, and avoids damage to circuit boards from repeated soldering.

Q2: In what applications or industries are relay sockets used most commonly?

A2: Relay sockets are used across a wide range of applications in electrical engineering. They are commonly found in industrial automation and control systems (for example, factory control panels and robotic machinery), power and energy systems (such as electrical switchgear, renewable energy installations, and battery storage systems), and automotive vehicles (cars, electric vehicles, and other transportation). They also appear in commercial and home automation – including HVAC controls, building security alarm panels, and smart home devices. Telecom and data center equipment use relay sockets for signal switching and power control in network infrastructure. Essentially, any application that uses relays for switching electrical circuits can benefit from a relay socket. By providing a standardized interface, relay sockets make it easier to design, maintain, and replace relays in all these industries.

Q3: How do I choose the right relay socket for my needs?

A3: Choosing the right relay socket depends on the relay and the application. First, match the socket to your relay’s pin configuration and type – for instance, an 8-pin octal relay needs a matching 8-pin socket. Check the socket’s voltage and current rating to ensure it can handle your circuit’s load (for safety, ratings should meet or exceed the relay’s and circuit’s requirements). Consider the mounting style you need: options include PCB-mounted sockets, panel-mounted ones, or DIN rail mounted sockets for industrial racks. The environment is also key – for harsh conditions (outdoor, automotive, or factory floor), choose sockets with durable, possibly sealed, housings that resist moisture, dust, and vibration. Look for additional features like retaining clips or brackets if the application involves motion or vibration, to keep the relay firmly in place. Finally, ensure the socket has appropriate approvals or certifications (e.g. UL listed, CE marked) if required for your project, as this indicates compliance with safety standards. By considering these factors – compatibility, electrical ratings, mounting, environmental durability, and certifications – you can select a relay socket that will perform reliably in your specific application.

Conclusion: From industrial automation and power grids to automotive electronics and smart homes, relay socket applications span nearly every sector of electrical engineering. These unassuming components provide a reliable, standardized interface for relays, making complex systems easier to build and maintain. The prevalence of the relay socket in electrical engineering underscores its importance across all these systems. Using the right relay socket is essential for safety and efficiency – it can dramatically reduce downtime and ensure your control or monitoring system operates smoothly. If you’re looking to implement or upgrade relays in your design, consider exploring our broad product catalog of quality relay sockets and accessories. We offer a wide range of relay bases and connectors for every application, backed by expert guidance. Contact us to find the perfect relay socket solution for your project or to get a quote – our team is here to help you enhance the reliability of your systems.